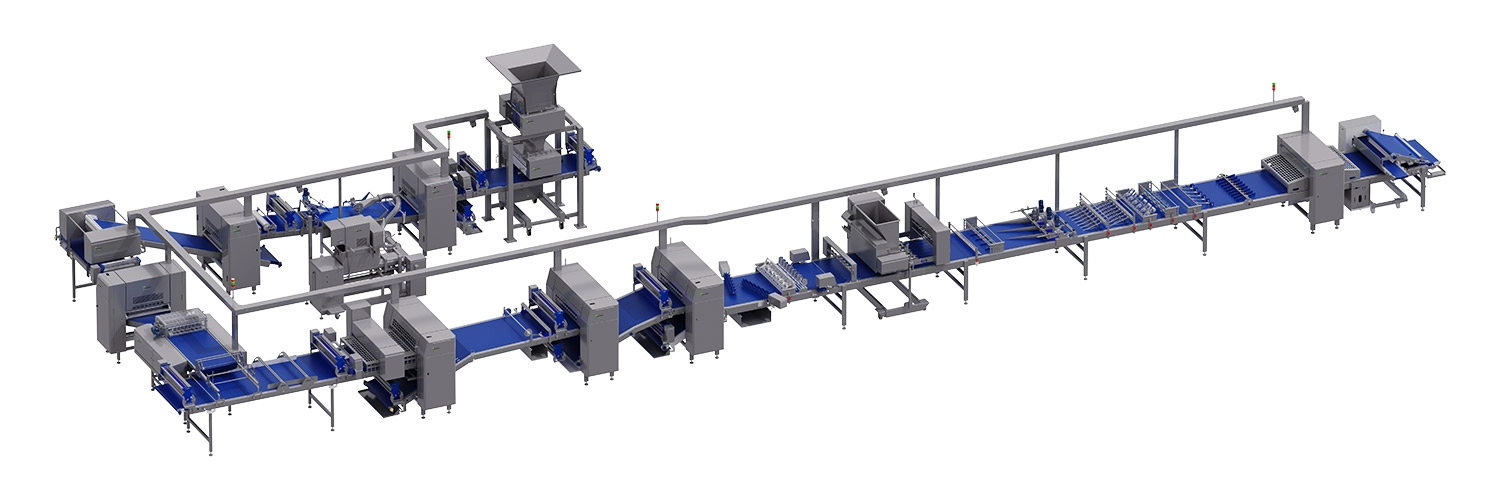

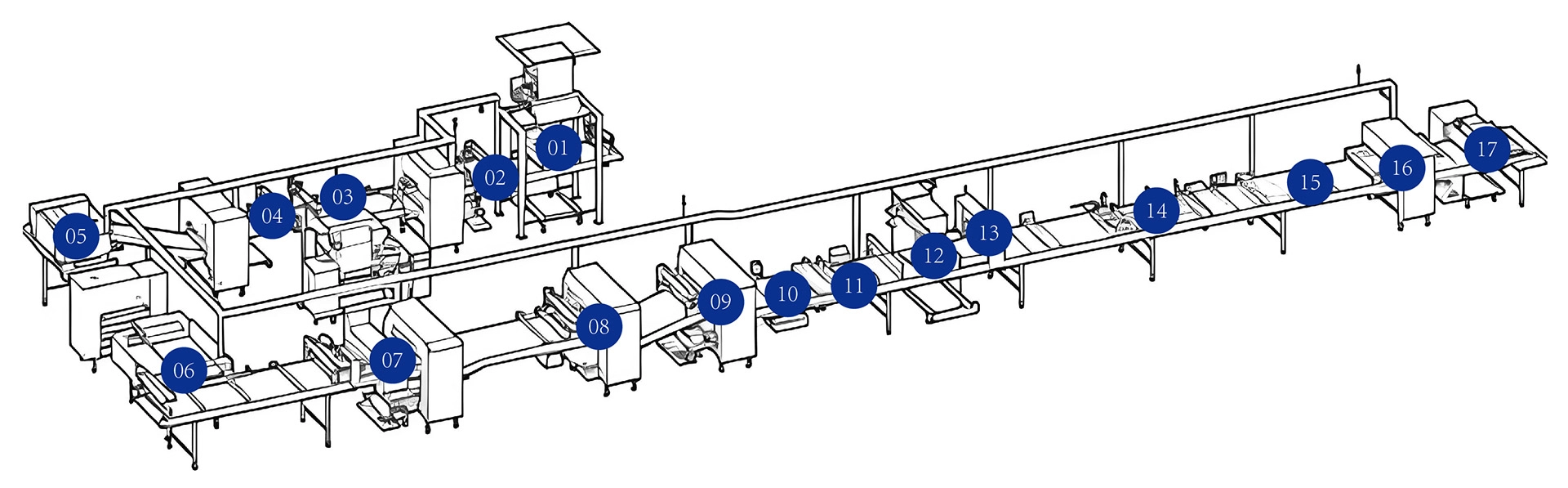

Our laminated pastry forming production line is a unique fusion of time-tested expertise and cutting-edge innovation. With unparalleled attention to detail, it supports versatile forming methods to meet both your production needs and consumer expectations. We deliver tailored, personalized solutions that position us as your ideal partner for baking production excellence.

Advanced Operating System for High-Efficiency Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime for Cost Savings

User-Friendly Operation via Smartphone, Tablet, PC, and Built-in Touchscreen

Intelligent Efficiency for Reduced Energy Consumption

• One System for Broader Product Range: With minimal component changes, this equipment enables production of diverse bread dough types, achieving multi-purpose use and cost savings.

• Custom Laminating Capabilities: Produce 10-100+ dough layers using fat-encasing, swing-folding, and draw-folding techniques, enabling scalable production of flaky pastry doughs per requirements.

• C-Configuration Production Line, Maximum Output can be 2,000 kg/h.

• Industrial-Grade Production Line with Forming Speed Up to 150 Cycles/Minute

• Dough Sheet Width: 600-800-1000-1200 mm; Thickness Range: 3-20 mm

• Seamlessly integrates with production systems while enabling rapid product changeover to ensure output capacity.

| Technical Parameters |

Equipment Dimensions: Effective Dough Sheet Width: Maximum Dough Output Capacity: Dough Sheet Thickness: Total Power Consumption: Air Pressure Requirement: Air Consumption Rate: Conveyor Belt Speed: |

25995*8219*3326mm 600-800-1000-1200mm 1-2.5T/h 1.5-20mm 40KW 0.6MPa(6kg/cm²) 2m³/min 1.5-8m/min |

| Applicable Dough Types |

Yeast-Free Laminated Dough Yeast-Leavened Laminated Dough Yeast-Free Shortcrust Laminated Dough Yeast Dough (Hydration 50-70%) |

|

| Operating Environment |

Floor Load Capacity: Ambient Temperature: Ambient Humidity: Vibration: Interference: |

Average Load ≥500kg/m² 1-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |