Advanced operating system for efficient production

Quick and easy cleaning mode

Innovative design to minimize downtime and reduce costs

User-friendly operation via smartphone, tablet, computer, and built-in touchscreen

Smart efficiency for reduced energy consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Stability of the dough formation is maintained through an advanced control system, that guarantees the precision of key processes in the production.

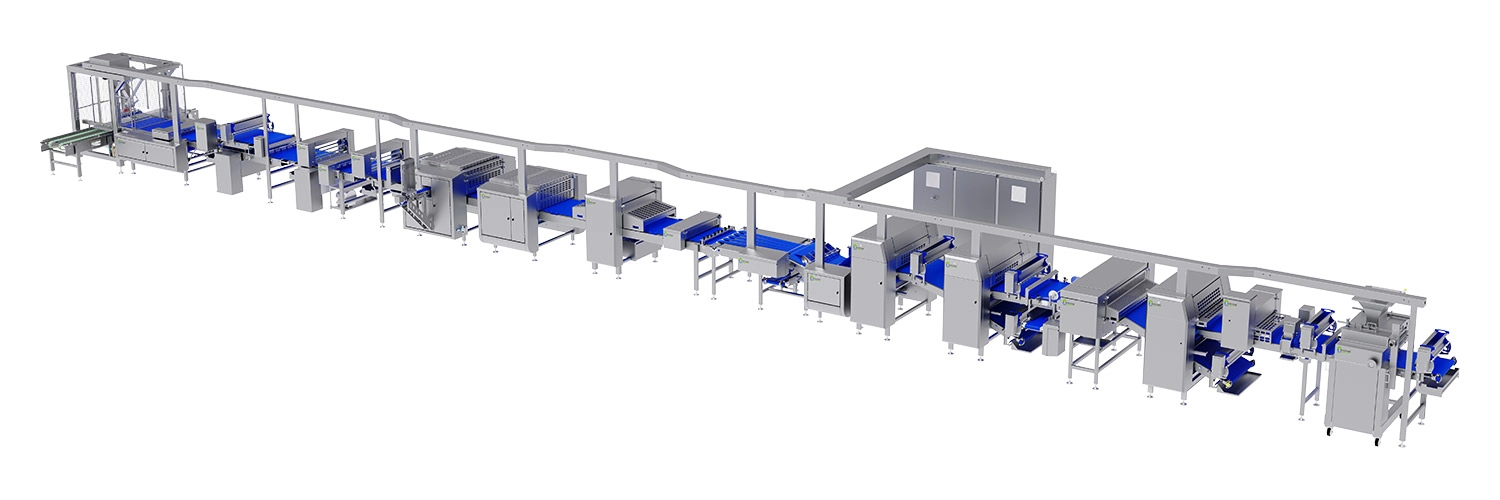

| Technical parameter |

Equipment Size: Maximum Production capacity: Power Supply Rated Power: Atmospheric Pressure: Gas Consumption: Conveyor Line Speed: |

30400*2330*2200mm >850-890kg/h AC380 / AC220 / DC24, 50Hz±1Hz,3∅+E+N 74KW 0.6MPa(6kg/cm²) 2000m³/min 430mm/s |

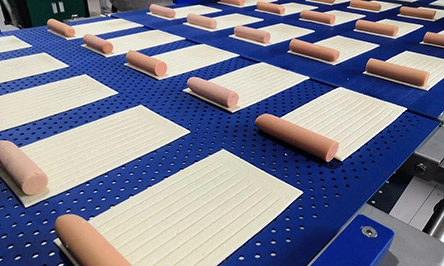

| Production scope |

All kinds of pies with and without filling |

|

| Dough range |

Yeast free crispy dough, mixed crispy cookie dough |

|

| Dough characteristics |

Suitable for lump dough and ribbon dough |

|

| Use Environment |

Ground Bearing Capacity Ambient Temperature Ambient Humidity Vibration Interfere Working Surface

Climate Noise |

Average ≧500kg/㎡ 5-40℃ Max 75% or less No frost, no dew Not greater than 0.5G No strong radio and other interference The machine must be installed on a surface with sufficient load-bearing capacity. The surface slope must not exceed 1%. Normal baking operating temperature (±15°C) <80 decibels |

| Electrical Data |

Maximum voltage deviation Electrical protection Total power Frequency Air consumption |

5% IP55 40 kW 50 Hz ≥1 m³/min |