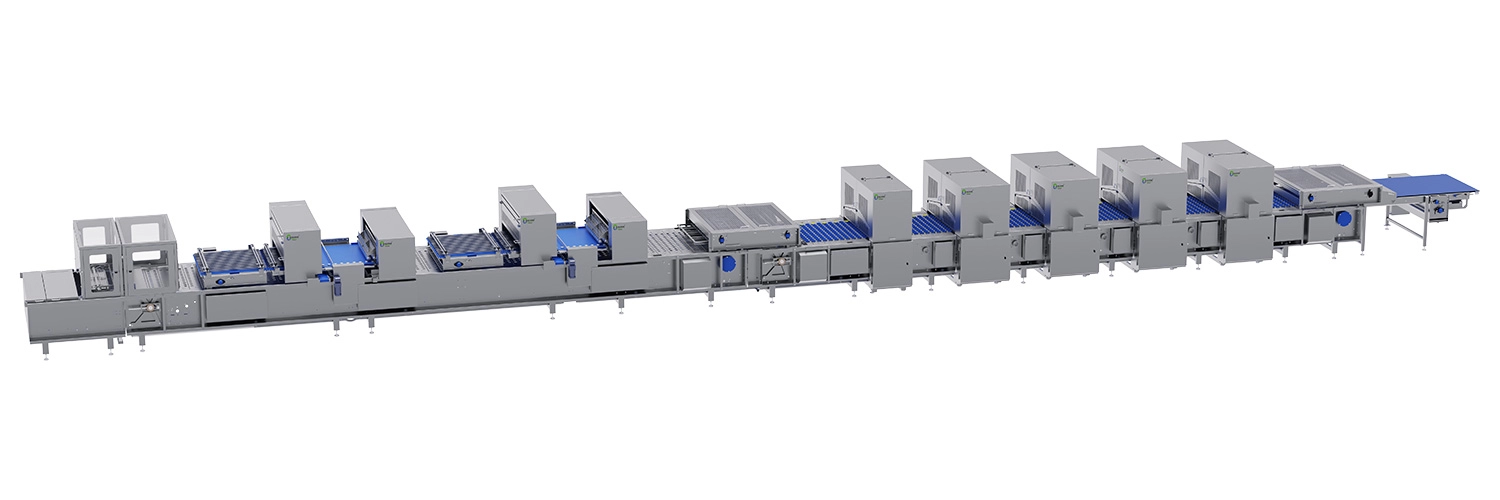

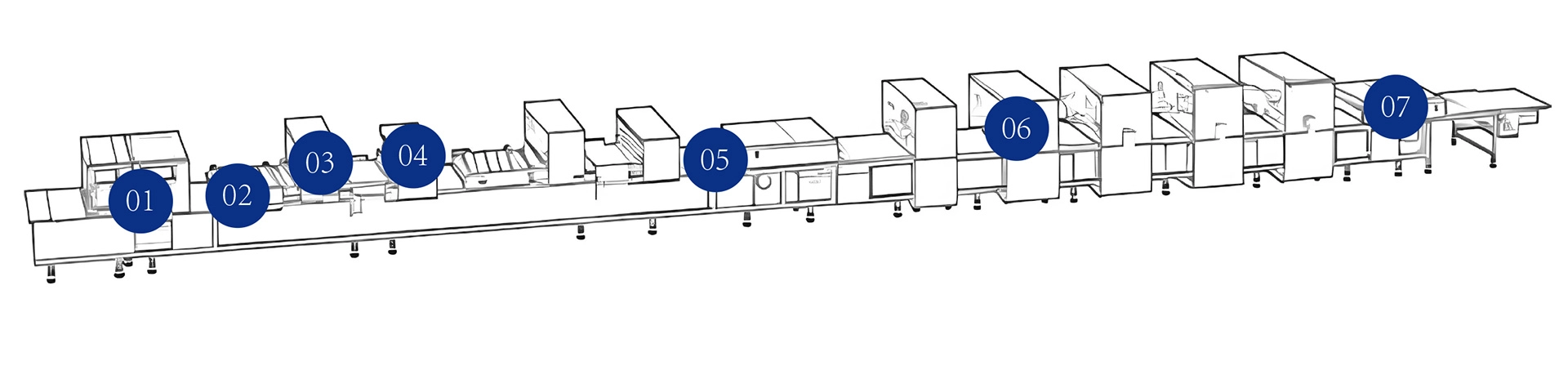

This production line is specially designed for producing handmade imitation egg tart shells, with a maximum capacity of 30,000 pieces per hour. The tarts are gently formed by a manual-mimicking shaping to secure each level of laminated dough. Hand imitation system guarantees crispy, airy shell after baking. By swapping bottom molds and forming dies within a defined range, different product sizes can be accommodated. The equipment complies with food safety production standards, features a low-dust environment, uses food-grade lubricant design and includes an emergency shutdown function.

Advanced Operating System for High-Efficiency Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime for Cost Savings

User-Friendly Operation via Smartphone, Tablet, PC, and Built-in Touchscreen

Intelligent Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Stability of the dough formation is maintained through an advanced control system, that guarantees the precision of key processes in the production.

| Technical Parameters |

Equipment Dimensions: Maximum Capacity: Power: otal Power Consumption: Air Pressure Requirement: Air Consumption Rate: Conveyor Belt Speed: |

25500*2400*2250mm >30000/h AC380V+10-15%, 50Hz±1Hz,3∅+E+N 142KW 0.6MPa(6kg/cm²) 2000m³/min 1.5-8m/min |

| Production Scope | Various filled and unfilled pies | |

| Applicable Dough Types |

Non-yeast laminated dough Blended laminated cookie dough |

|

| Dough Characteristics | Suitable for both block-shaped and strip-shaped dough | |

| Operating Environment |

Floor Load Capacity: Ambient Temperature: Ambient Humidity: Vibration: Interference: |

Average Load ≥500kg/m² 1-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |