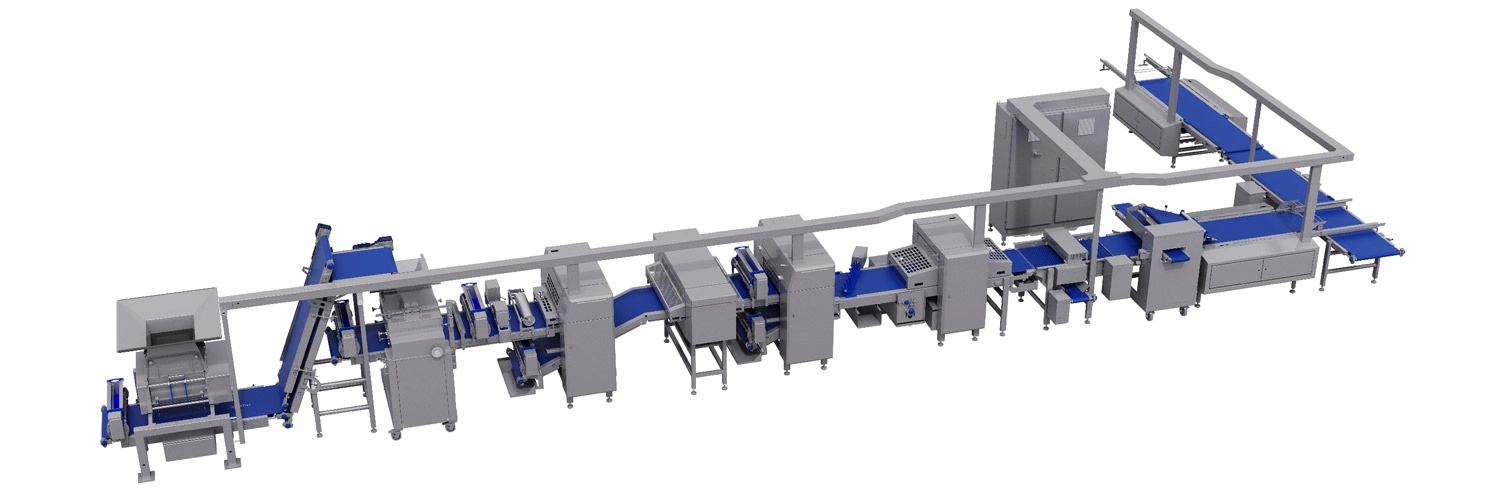

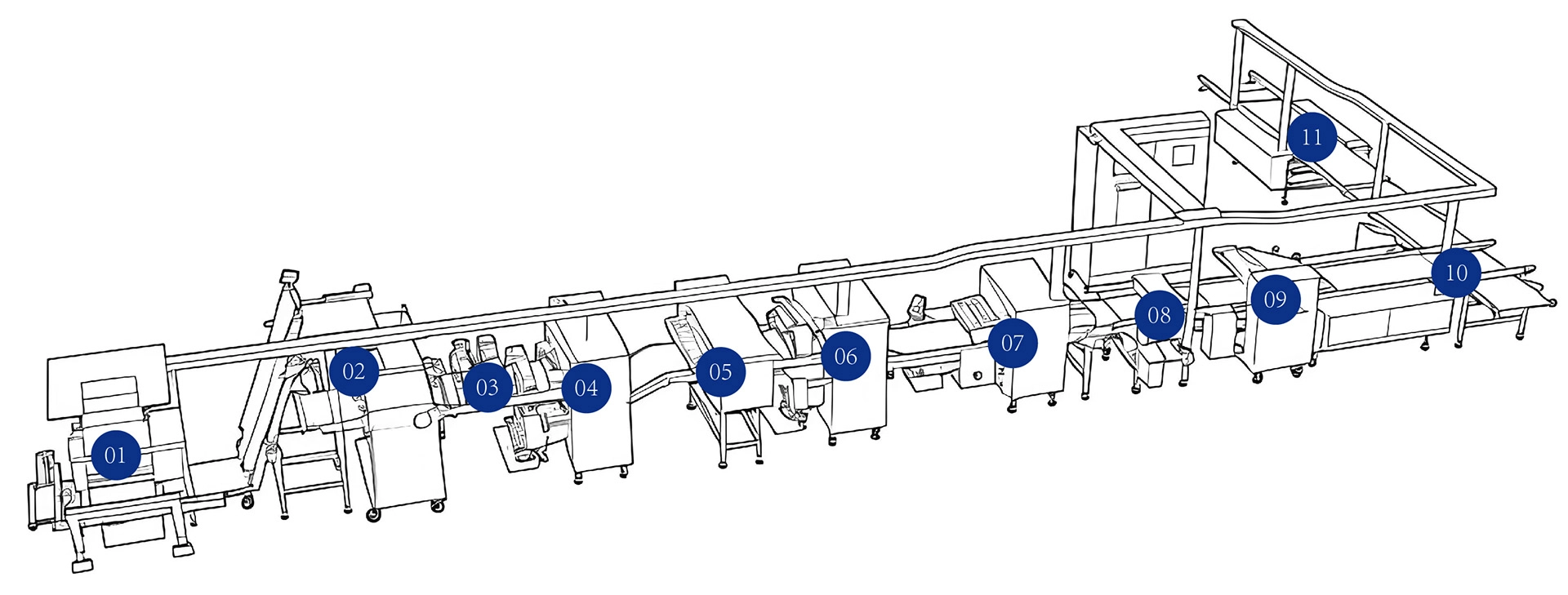

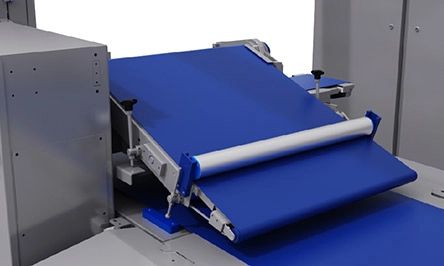

An advanced dough formation line is specifically designed for donut production. This line carefully and efficiently forms donuts of any shape from a yeast dough sheet. With its outstanding automation technology and precise control system, it can easily meet the diverse donut demands in the market.

Production Scope: It supports the production of donuts in various shapes, flavors, and decorations, including classic round, decorative, as well as special-shaped and flavored donuts. Whether traditional or innovative styles, our production line ensures the efficiency and precision of the dough shaping process.

Advanced Operating System for High-Efficiency Production

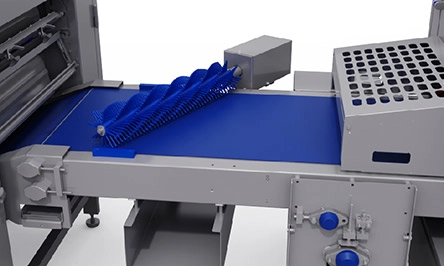

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime for Cost Savings

User-Friendly Operation via Smartphone, Tablet, PC, and Built-in Touchscreen

Intelligent Efficiency for Reduced Energy Consumption

• Dough Sheet Width: 600-800-1000-1200 mm; Thickness Range: 3-20 mm.

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Pizza formation line produces uniformly textured and even dough sheets with minimal stress to create high-quality baked products with precise weight control.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Stability of the dough formation is maintained through an advanced control system, that guarantees the precision of key processes in the production

• Designed with quick-disassembly and washable components, reducing both cleaning/maintenance difficulty and costs.

| Technical Parameters |

Equipment Dimensions: Effective Dough Sheet Width: Maximum Dough Output Capacity: Dough Sheet Thickness: Rated Power: Air Pressure Requirement: Air Consumption Rate:

Conveyor Belt Speed: |

18800*7500*3400mm 600-800-1000-1200mm 2T/h 15-25mm 40KW 0.6MPa(6kg/cm²) 2m³/min 3m/min |

| Applicable Dough Types |

This production line specializes in the shaping of yeast dough. |

|

| Operating Environment |

Floor Load Capacity: Ambient Temperature: Ambient Humidity: Vibration: Interference: |

Average Load ≥500kg/m² 1-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |