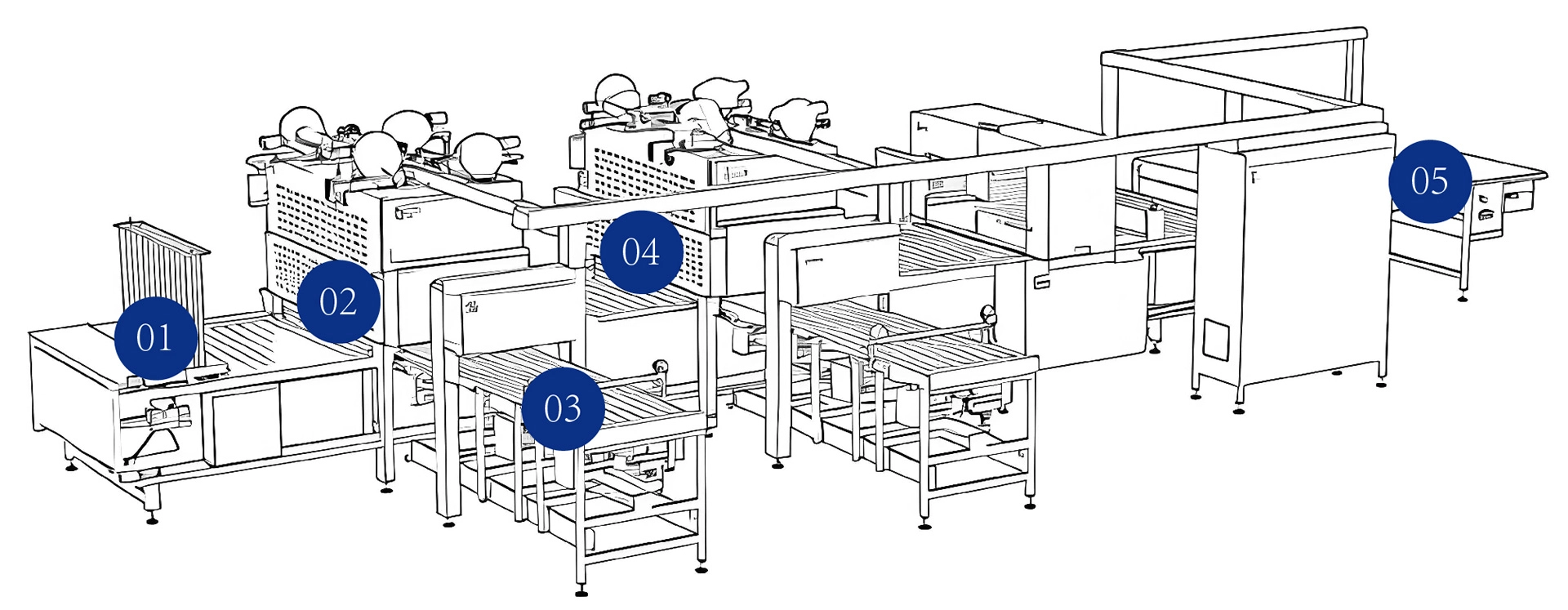

Hong Kong-style Egg Tart Formation Line is capable of forming a variety of egg tart shells, with a maximum throughput of 624 pieces per minute. The line is designed according to the highest automatization levels and only requires a single operator at the control panel. It supports automatic placement of aluminum foil cups, automatic shell placement, automatic stamping/forming, and automatic transfer of finished products.

The equipment is equipped with multiple forming dies for various tart shell products. The movable disk molds are detachable to facilitate product changes and cleaning/maintenance. The conveyor chain with empty trays and the stamping mechanism operates in a stable coordination. Stamping heads feature heating and air-assisted demolding.

Advanced Operating System for High-Efficiency Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime for Cost Savings

User-Friendly Operation via Smartphone, Tablet, PC, and Built-in Touchscreen

Intelligent Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Stability of the dough formation is maintained through an advanced control system, that guarantees the precision of key processes in the production.

| Technical Parameters |

Equipment Dimensions: Maximum Capacity: Power: Total Power Consumption: Pressure Requirement: Air Consumption Rate: Conveyor Belt Speed: |

13466*4573*2474mm >37440/h AC380V+10-15%, 50Hz±1Hz,3∅+E+N 65KW 0.6MPa(6kg/cm²) 2000m³/min 430mm/s |

| Production Scope |

Various filled and unfilled pies |

|

| Applicable Dough Types |

Non-yeast laminated dough Blended laminated cookie dough |

|

| Dough Characteristics |

Suitable for lump dough and ribbon dough |

|

| Operating Environment |

Floor Load Capacity: Ambient Temperature: Ambient Humidity: Vibration: Interference: |

Average Load ≥500kg/m² 1-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |