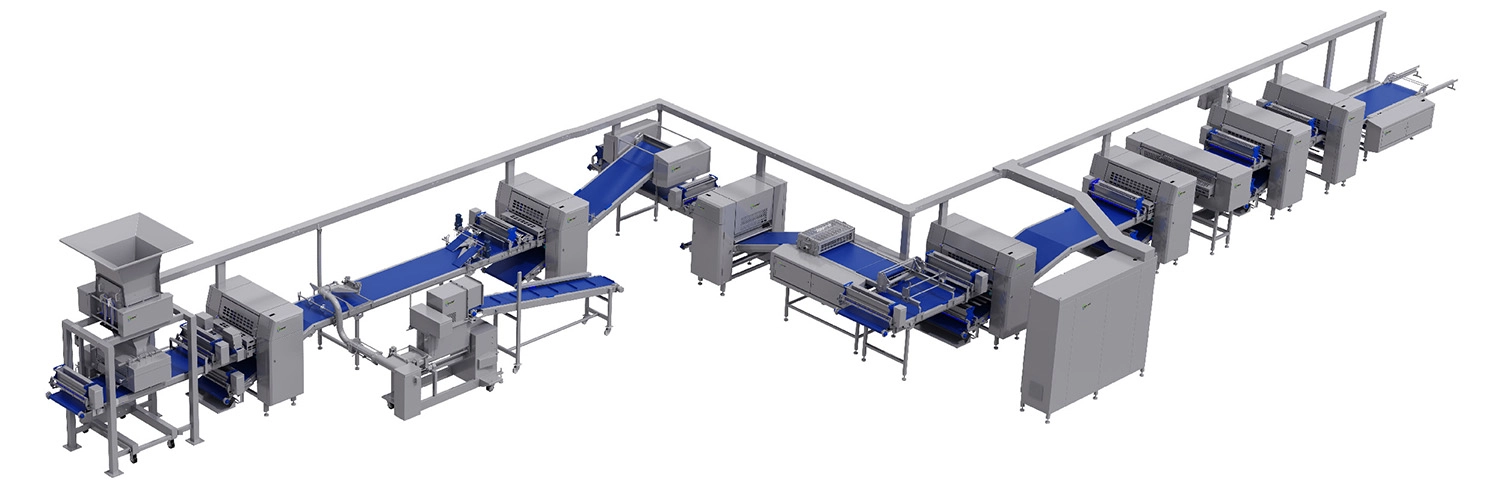

Laminated Dough Sheeting Line: Adjustable width, thickness, and layer count for multi-specification dough sheet production.

Advanced Operating System for High-Efficiency Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime for Cost Savings

User-Friendly Operation via Smartphone, Tablet, PC, and Built-in Touchscreen

Intelligent Efficiency for Reduced Energy Consumption

• One System for Broader Product Range: With minimal component changes, this equipment enables production of diverse bread dough types, achieving multi-purpose use and cost savings.

• Custom Laminating Capabilities: Produce 10-100+ dough layers using fat-encasing, swing-folding, and draw-folding techniques, enabling scalable production of flaky pastry doughs per requirements.

• Z-Configuration Production Line, Maximum Output can be 2,000 kg/h./p>

• Industrial-Grade Production Line with Forming Speed Up to 150 Cycles/Minute.

• Dough Sheet Width: 600-800-1000-1200 mm; Thickness Range: 3-20 mm.

• Seamlessly integrates with production systems while enabling rapid product changeover to ensure output capacity.

| Technical Parameters |

Equipment Dimensions: Effective Dough Sheet Width: Maximum Dough Output Capacity: Dough Sheet Thickness: Total Power Consumption: Air Pressure Requirement: Air Consumption Rate:

Conveyor Belt Speed: |

38491*8564*3326mm 600-800-1000-1200mm 2T/h 1.5-10mm 50-140KW 0.6MPa(6kg/cm²) 2m³/min 2-12m/min |

| Applicable Dough Types |

Yeast-Free Laminated Dough Yeast-Leavened Laminated Dough Yeast-Free Shortcrust Laminated Dough Yeast Dough (Hydration 50-70%) |

|

| Operating Environment |

Floor Load Capacity: Ambient Temperature: Ambient Humidity: Vibration: Interference: |

Average Load ≥500kg/m² 1-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |