From May 19 to 22, 2025, the 27th China International Bakery Exhibition (Bakery China 2025)—the annual global baking industry gathering—grandly convened at the National Exhibition and Convention Center (Shanghai) in Hongqiao. Centered on the theme “Innovation Drives, Connecting the World,” this year's exhibition spanned over 330,000 square meters, gathering more than 2,200 industry-leading enterprises from over 30 countries and regions. As an innovator in intelligent food industrial robotics, Hengjiang Intelligent Technology Co., Ltd. (hereinafter referred to as “Hengjiang Intelligent”) made a significant appearance in Hall 1.1's “Baking Production Equipment” zone (Booth No.: 11B18) with its cutting-edge flexible automation solutions. Aligning closely with the exhibition's “First Intelligent Baking Festival” focus on industrial smart upgrades, Hengjiang Intelligent provided a novel “smart manufacturing” solution to address efficiency and quality bottlenecks in traditional baked goods production.

Industry Challenges and Contemporary Demands: Flexible Automation Emerges as a Critical Breakthrough

Currently, while the baking and frozen food industries experience rapid market growth, they also face significant challenges. On one hand, consumer demands for product freshness, diversity, and personalization continue to rise. On the other, traditional food production lines—particularly in the final sorting and packaging stages for fragile items like pastries and egg tarts—have long relied on labor-intensive methods. This not only creates efficiency bottlenecks but also burdens enterprises with recruitment difficulties, high costs, and inconsistent standardization. Achieving high-speed, high-precision automation without damaging products has become a critical challenge for the industry's transition toward “new quality productivity.”

The solution showcased by Hengjiang Intelligent directly addresses this core pain point. Leveraging its proven expertise in automated packaging for egg tarts, puff pastries, and bread, the company demonstrates how its equipment forming lines and robots—equipped with proprietary adaptive flexible gripping technology and high-speed precision motion control—consistently handle the grasping, transfer, and precise stacking of diverse, irregularly shaped, and fragile baked goods on simulated production lines.

Hengjiang Solution: The Harmonious Integration of Precision and Flexibility

At Hengjiang Intelligent's booth, the robotic demonstration unit serves as the ultimate testament to its technological prowess. Its core advantages manifest in three dimensions:

Precision Control for Damage-Free Handling: For products like egg tarts and baked pastries that are highly susceptible to breakage and deformation during transport, Hengjiang robots achieve millimeter-level micro-adjustments in force and angle through force-position hybrid control and vision-assisted positioning. This not only ensures flawless product appearance but also prevents internal filling displacement, minimizing losses traditionally unavoidable with manual or rigid automation.

Ultimate Flexibility for Diverse Applications: Addressing the market trend of “small batches, multiple varieties,” Hengjiang Intelligent's robotic workstation system demonstrates exceptional adaptability. Through rapid end-of-arm tooling (EOAT) changes and instant control program adjustments, a single robot effortlessly handles products of varying specifications and shapes, along with different-sized trays and packaging boxes. This significantly enhances production line utilization and return on investment.

End-to-End Food Safety Assurance: Upholding a “quality-first” philosophy, all Hengjiang Intelligent robot components in direct contact with food are constructed from food-grade stainless steel, meeting stringent food safety standards. Incorporating cleanroom design principles, the robot body facilitates easy cleaning and disinfection, eliminating contamination risks at the hardware level and satisfying the baking industry's high cleanliness requirements for production environments.

Integrating into the Industrial Ecosystem, Co-Creating a Smart Future

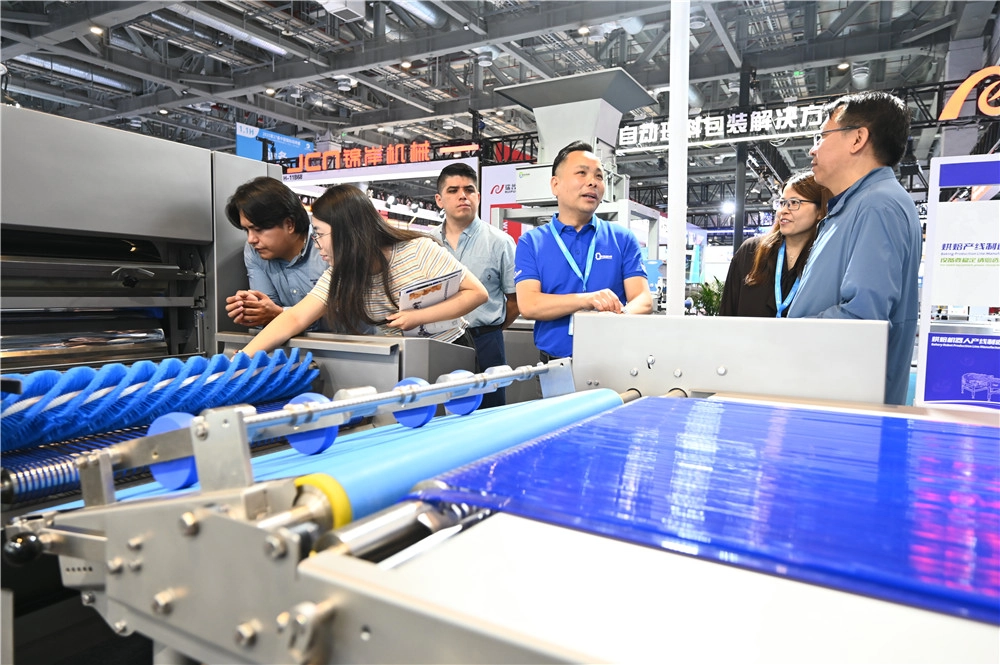

Hengjiang Intelligent's debut represents more than a single product showcase—it actively responds to the broader trend of intelligent transformation across the baking industry. During the exhibition, Hengjiang Intelligent's booth drew numerous industry professionals from large-scale baking factories, central kitchens, pre-baked goods brands, and food machinery integrators for in-depth discussions. Numerous domestic and international visitors expressed keen interest in the robots' ability to resolve practical production bottlenecks, engaging in in-depth discussions about automation possibilities for specific products. Hengjiang Intelligent's technical team also exchanged insights with industry partners on cutting-edge topics such as “AI Quality Inspection and Robot Sorting Integration” and “End-to-End Digital Line Management,” jointly exploring deeper collaboration opportunities.

Conclusion: Craftsmanship Forges Industrial Intelligence

From the perfect packaging of a single pastry to the intelligent evolution of an entire production line, Hengjiang Intelligent's presentation at Baking Expo China 2025 embodies a new interpretation of “craftsmanship” in the era of industrial automation. Facing the growing demand for flexibility and intelligence in the baking industry, Hengjiang Intelligent is driving the evolution of production lines from “mechanical repetition” to “intelligent perception and decision-making” through solid technological innovation and deep industry understanding.