Driven by the dual pursuit of production efficiency and product quality, Guangzhou Aokun Food Co., Ltd. and Jiaxing Hengjiang Intelligent Technology Co., Ltd. have once again joined forces to embark on an automation innovation journey for Hong Kong-style egg tart production lines. The core project of this collaboration—the HJ.PTC24 Hong Kong-style Egg Tart Molding Production Line—not only signifies Aokun's solid stride into production automation but also represents a perfect fusion of both parties' technical prowess and innovative capabilities.

HJ.PTC24 Hong Kong-style Egg Tart Molding Production Line

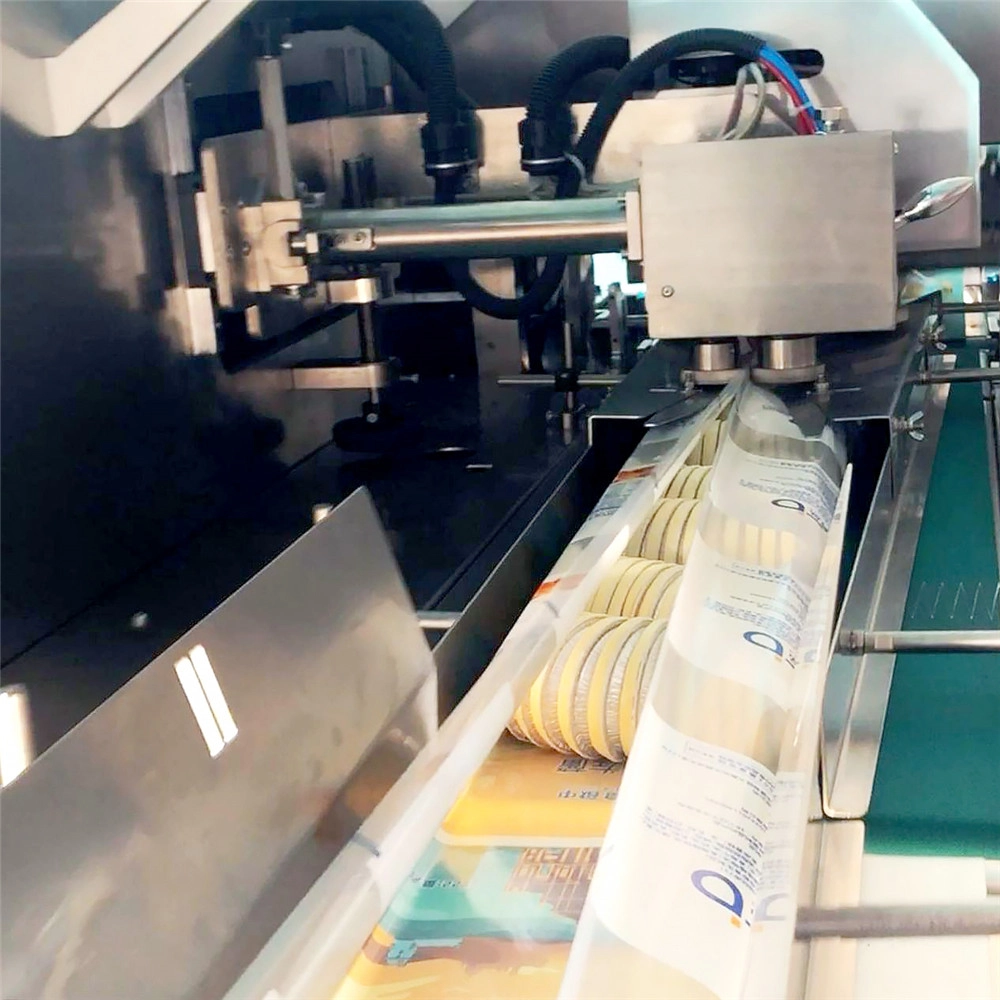

This production line is specifically designed for Aokun's five flagship egg tart crusts, aiming to achieve fully automated production while enhancing output and quality. Featuring fully automated functions including aluminum foil cup placement, pastry sheet feeding, stamping molding, and finished product discharge, it accommodates five tart shell specifications: 2103, 2107, 2105, premium mini, and 25g premium. Maximum output reaches 624 pieces per minute.

In system design, Hengjiang Intelligent thoroughly considered actual production site conditions, constructing equipment frames from SUS304 stainless steel to ensure stability and durability. All food-contact surfaces utilize food-grade materials, strictly guaranteeing food safety. The selection of stainless steel/copper alloy for the stamping die head ensures durability while maintaining uniform heating, reflecting an extreme attention to detail.

The HJ.PTC24 production line achieves full automation across the entire process: from dough sheet conveyance, center coordinate detection, aluminum foil cup placement, dough sheet gripping and placement, stamping and forming, to finished product conveyance. This series of automated operations not only significantly boosts production efficiency but also substantially reduces labor costs. Whereas the production line previously required 18-20 operators, it now runs efficiently with only about 4 personnel. The comprehensive wage per worker has also decreased from approximately ¥8,000 to a more economical level.

In terms of return on investment, the introduction of the HJ.PTC24 line has boosted Aokun's egg tart shell production capacity to a maximum of 37,440 pieces per hour, far exceeding the 28,800–37,440 pieces per hour achievable manually. Although the total equipment investment reached 2 million yuan, this investment will yield substantial economic benefits and market competitiveness for Aokun in the long run.

Through this collaboration, Aokun firmly believes that selecting Hengjiang Intelligent as a partner was a wise decision. Hengjiang Intelligent not only provided advanced technical support but also introduced innovative production concepts and management models. Looking ahead, Aokun will continue to deepen its partnership with Hengjiang Intelligent, jointly exploring further possibilities in intelligent production to deliver higher-quality, more delicious Hong Kong-style egg tarts to consumers.