Scara-type modular robotic sorting workstation, meticulously crafted by Hexeon Intelligent Technology, is a cornerstone of Hexeon smart factory solutions. Integrating Hexeon patent Scara robot technology, this high-end intelligent equipment is designed to meet the automation demands of modern food industries and precision manufacturing sectors. With its exceptional performance and flexibility, it leads the new trend in food industry automation.

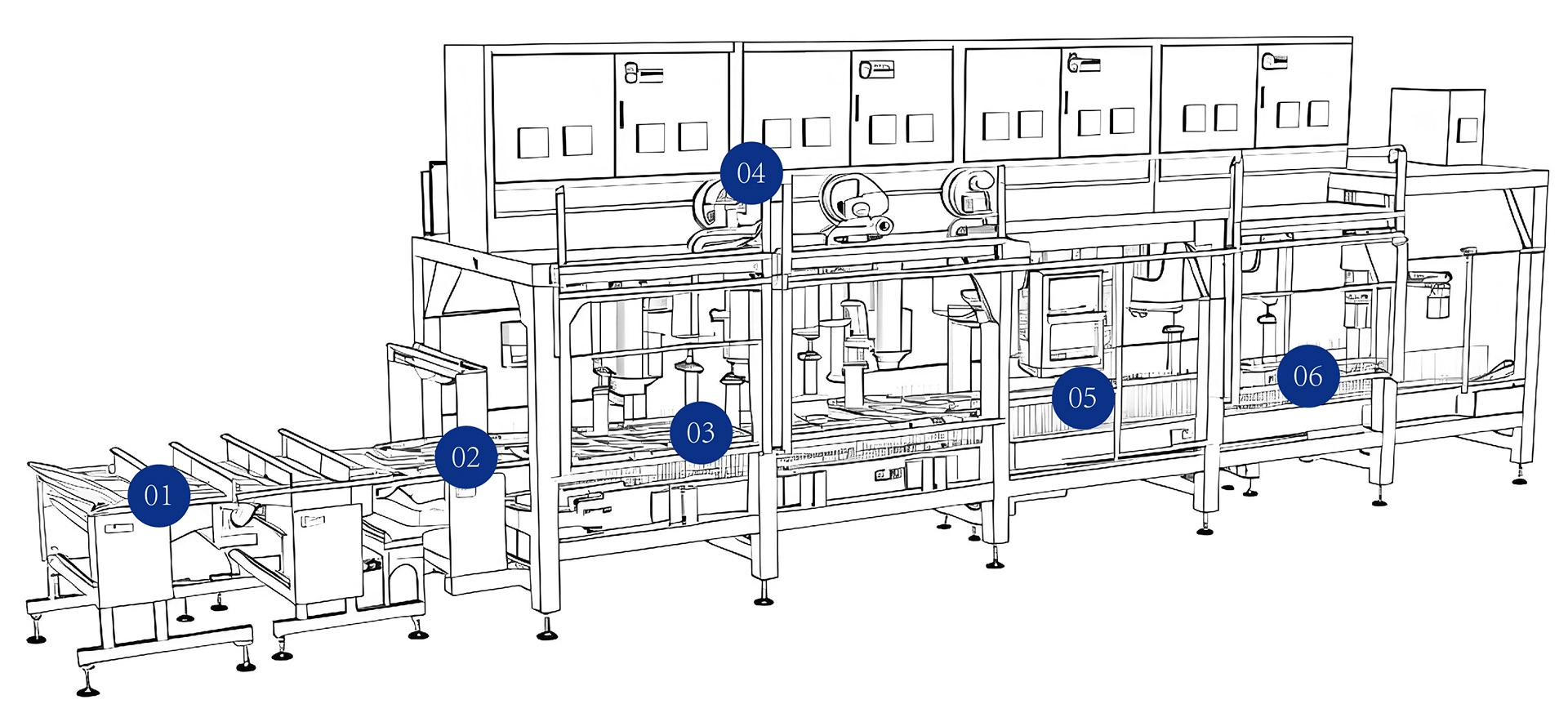

01 Buffer Docking

02 Vision System

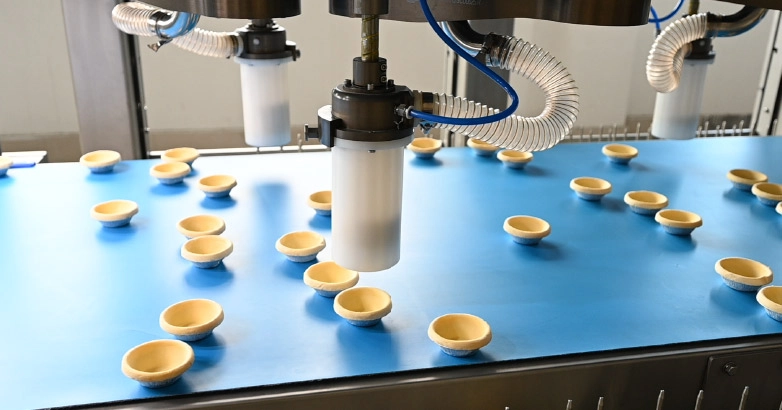

03 Actuator Assembly & Stacking Conveyor System

04 Negative Pressure System

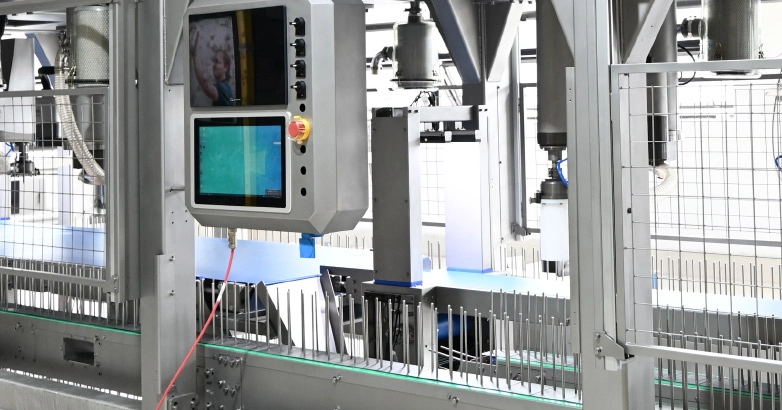

05 Human-Machine Interface (HMI) System

06 Aggregation System

Advanced Operating System for Efficient Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime to Cut Costs

User-Friendly Operation via Mobile, Tablet, PC, and Built-In Touchscreen

Smart Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Precise control: advanced control system ensures stability of operation.

| Technical Parameters |

Equipment Dimensions: Voltage: Power Supply Capacity: Air Pressure Requirement: Flow Rate: Maximum Capacity: Gas Consumption: Conveyor Belt Line Speed: |

10000*1830*3020mm AC380V+10-15% >215KVA >0.6MPa(6Kg/cm²) >2m³/min 624 per/min 2000m³/min 430mm/s |

| Product Advantages |

Superior Environmental Adaptability: Tailored for the stringent conditions of the food industry, the Hengjiang Scara robot workstation operates stably in sub-zero temperatures, ensuring uninterrupted production regardless of external environments. High-Speed, High-Precision Grasping: Equipped with advanced drive systems and precision mechanical design, the robot executes rapid and accurate product grasping, meeting strict requirements for food packaging and sorting. Efficient Automated Workflow: Integrating intelligent control, vision recognition, and material handling systems, the workstation achieves full automation—from grasping, stacking, and conveying to aggregation—significantly boosting productivity. Food Safety Compliance: Designed to meet food-grade safety standards, the workstation features dust-free construction and food-grade lubricants, ensuring hygienic production environments and product quality. Modular Design: The workstation’s modular architecture allows flexible configuration and scalability to meet evolving production needs, reducing upgrade costs and downtime for enterprises. |

|

| Operating Environment |

Floor Load Capacity Ambient Temperature Ambient Humidity Vibration Interference |

Average Load ≥500kg/m² 5-40℃ Max75% or less No frost, no dew ≤0.5G Free from Strong Radio/Electromagnetic Interference |