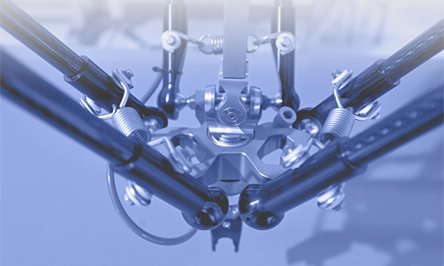

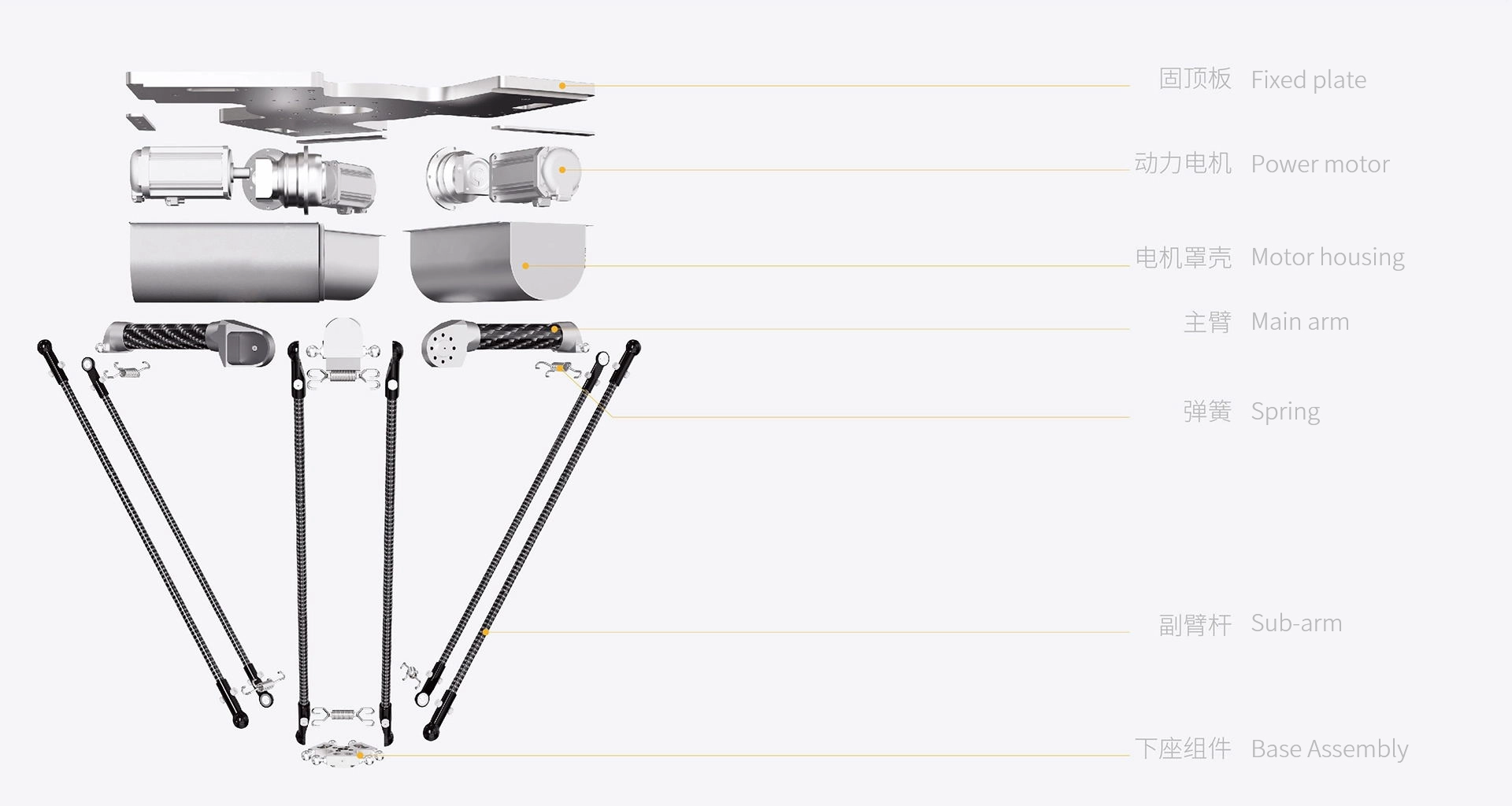

Delta robot comprises three parallel arms, each joint is connected to a fixed upper platform base. Lightweight design based on carbon fiber ensures efficient use of energy and emphasizes speed and accuracy rather than heavy payload capacity. This design enables rapid and precise motion in three-dimensional space, making it ideal for high-speed, high-precision tasks. It is well-suited for fast color, shape and quality-control sorting, pick-and-place and packaging operations. With exceptionally high precision, it supports fast, high-frequency actions. Common applications include rapid picking, packaging, sorting, and labeling, especially in scenarios requiring speed and precision, such as in the food industry production and packaging lines.

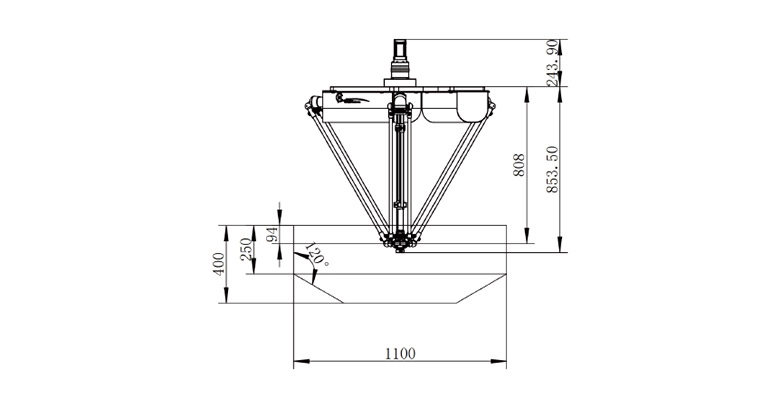

Exterior and Work Envelope

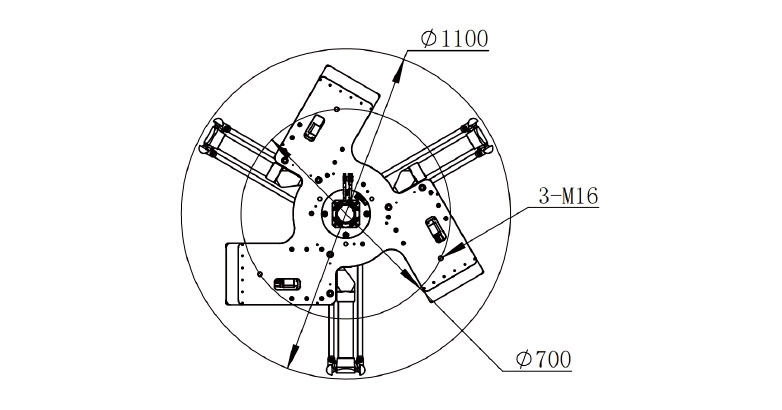

Base Diagram

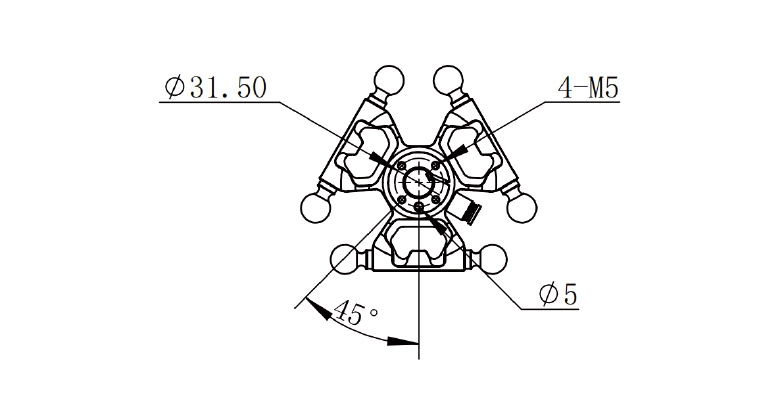

Flange End-Effector Diagram

Flexible Configuration Tasks

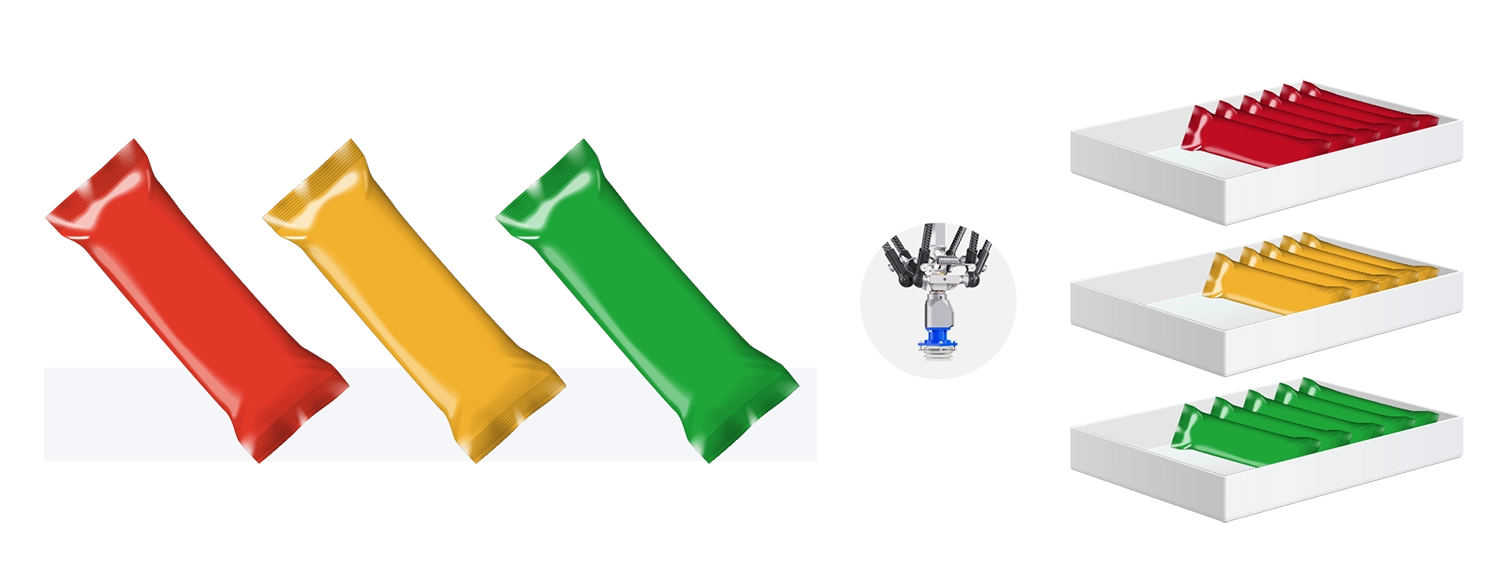

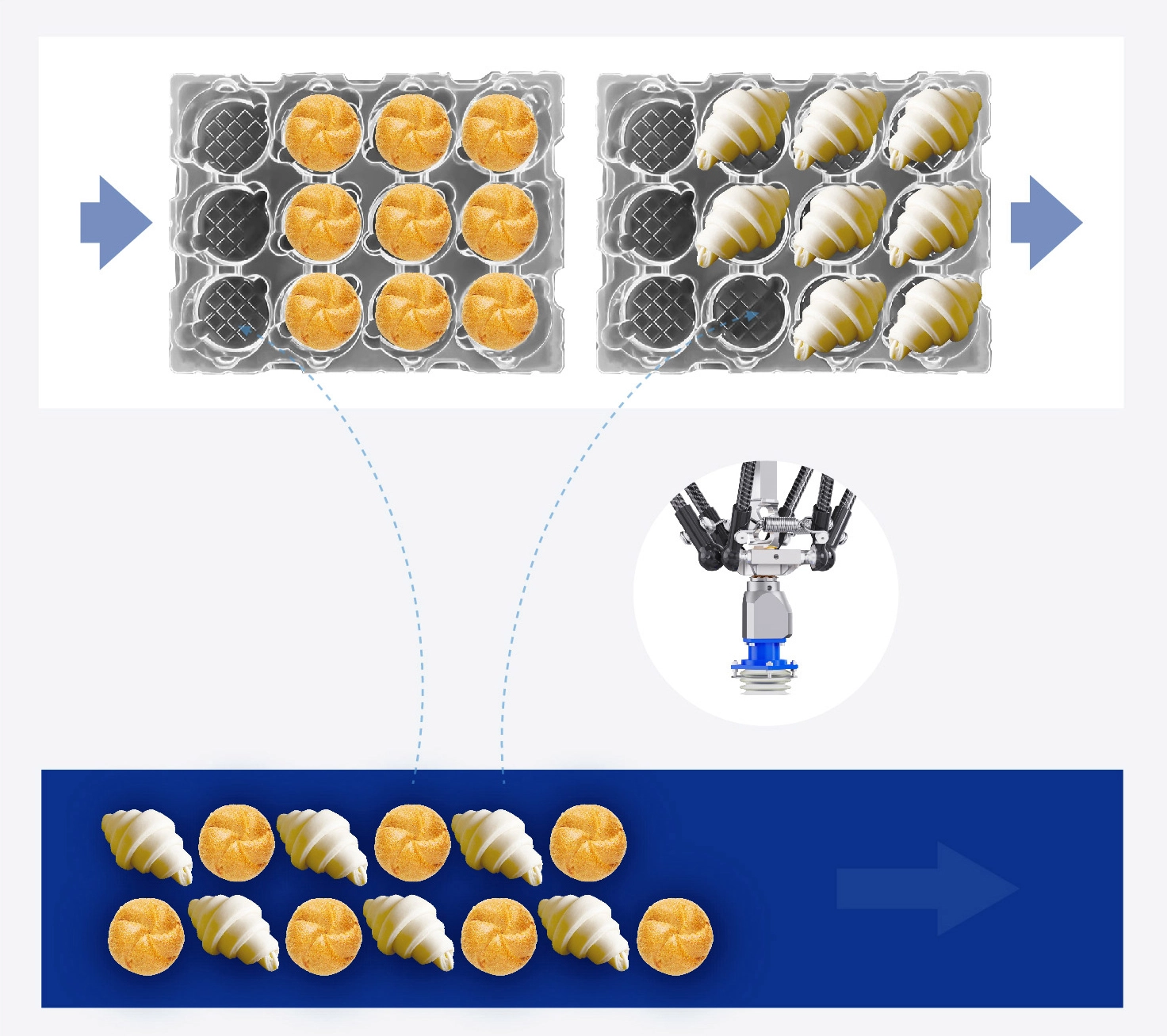

Delta Robot Picking and Sorting

Rotational axis can neatly arrange chaotic incoming materials, including bars, squares, and circles

Stable Working Quality

Most Delta robot components use Food-Grade 304 stainless steel

Labour reduction according to robot ratio

Connected to Hengjiang’s self-developed digital operating system

System Solution

Advanced sensing and control

Carbon fiber rods: sturdy yet lightweightt

High precision, high frequency

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• TThe robot system is capable of sorting unordered incoming materials onto a separate conveyor belt for neat discharge into the packaging area.

• Precise control: advanced control system ensures stability of operation.

• Unique design allows to combine high speed and high precision to ensure stable, efficient product grabbing, stacking, and conveying even in freezing environments, greatly enhancing line automation and production efficiency.

• Design flexibility: Simple adjustments enable sorting and packaging of a wide range of products (e.g., frozen donuts, frozen dumplings, frozen buns), medicines, electronics, and consumer, daily chemical items.

• Efficient, flexible, and precise characteristics significantly reduce production costs, elevate line automation and production efficiency, and improve product quality and market competitiveness.

| Capable of sorting three or more bagged incoming streams by color into neat packaging. |  |

| Capable of grabbing differently shaped incoming materials and neatly placing them into plastic trays; once trays are full, they are conveyed to the packaging system for the next step. |  |

EFFICIENTFLEXIBLEPRECISE

Delta Robot Grippers Examples

By adjusting the gripper design to suit different incoming materials, the system can finely grasp, sort, and carton a wide range of items.

To ensure food integrity and safety, grippers use food-grade materials; gripper styles are matched to product shape and characteristics to place items precisely into packaging boxes or other containers with neat, conveyor-fed transfer to the next stage. |

|

| Product Details |

Product Model: Rated Working Envelope: Effective Load: Protection Level: Noise Level: Pick-up Speed: Repetition Positioning Accuracy: Weight: Mounting Method : |

HJ-D11003-1 Non-Rotating Axis Model H(250-400)mm∅(580-1100)mm 6-20Kg IP65 <68dB(A) 40-100P/min ±0.2mm 92Kg Suspension Mounting |

| Product Advantage |

High-speed Cadence: The robot performs fast sorting at up to 55 cycles per minute, automatically adjusting the stacking quantity to ensure attractive and stable packaging. Low Dynamic Inertia: The parallel-linkage structure minimizes inertia during movement, enabling faster, more agile responses. Small Footprint: Compact design maximizes effectiveness in limited spaces, boosting line space utilization. Lightweight: The lightweight design reduces the device’s own load and lowers energy consumption, improving energy efficiency. Low Cumulative Error: A high-precision control system combined with robust mechanical design ensures minimal cumulative error over long-term operation, stabilizing product quality. Collaborative Operation: Multiple Delta robots configured in parallel form a modular collaborative system; each robot operates independently yet cooperates to handle incoming materials, transport, and stacking. High-precision Control: Advanced control algorithms and sensor technologies enable precise execution of every action, meeting the needs of meticulous operations. |

|

| Product Details |

Product Model: Rated Working Envelope: Effective Load: Protection Level: Noise Level: Pick-up Speed: Repetition Positioning Accuracy: Weight: Mounting Method : |

HJ-D11003-1 Rotary Axis Variant H(250-400)mm∅(580-1100)mm 6-20Kg IP65 <68dB(A) 40-100P/min ±0.2mm 92Kg Lifting |

| Product Advantage |

High-speed Cadence: The robot performs fast sorting at up to 55 cycles per minute, automatically adjusting the stacking quantity to ensure attractive and stable packaging. Low Dynamic Inertia: The parallel-linkage structure minimizes inertia during movement, enabling faster, more agile responses. Small Footprint: Compact design maximizes effectiveness in limited spaces, boosting line space utilization. Lightweight: The lightweight design reduces the device’s own load and lowers energy consumption, improving energy efficiency. Low Cumulative Error: A high-precision control system combined with robust mechanical design ensures minimal cumulative error over long-term operation, stabilizing product quality. Collaborative Operation: Multiple Delta robots configured in parallel form a modular collaborative system; each robot operates independently yet cooperates to handle incoming materials, transport, and stacking. High-precision Control: Advanced control algorithms and sensor technologies enable precise execution of every action, meeting the needs of meticulous operations. |

|

| Operating Environment |

Floor Load Capacity Vibration Interference |

Average Load ≧500kg/㎡ ≤0.5G Free from Strong Radio/Electromagnetic Interference |