SCARA robot is independently developed by Hexeon and built with a brand-new upgraded design. It adopts a hanging installation and integration of drive, control, and electricity, resulting in a streamlined overall structure with minimal cabling and a small footprint. The hardware and software are modular, which significantly lowers maintenance costs and simplifies installation and commissioning. It also supports remote network monitoring and maintenance.

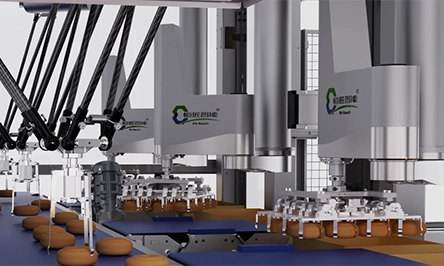

The robot is equipped with an intelligent vision control system and, in conjunction mwith flexible operations, effortlessly achieves intelligent and convenient handling. It adopts a horizontal multi-joint design, which not only improves precision but also significantly enhances load-bearing capacity, making it suitable for large-scale operational spaces and medium-to-heavy load work scenarios, with a maximum load capacity of 15-30Kg. Additionally, the robot boasts extremely high repeat positioning accuracy, up to ±0.025mm, and has a wide range of application scenarios, covering an operational space of 500mm - 700mm. It offers high degrees of freedom and efficient space utilization.

HJ-SC1250-R robot is independently developed by Hexeon and is crafted with a brand-new upgraded design. The overall equipment is compact and lightweight, featuring a ceiling-mounted installation and an all-in-one design, providing high degrees of freedom and efficient space utilization. The entire machine weighs only 40Kg. With flexible operations paired with an intelligent vision system, it easily achieves intelligent and convenient handling. It has a wide range of application scenarios, covering an operational space of 500mm-700mm, and offers high precision, with repeat positioning accuracy up to ±0.025mm.

Flexible Configuration Tasks

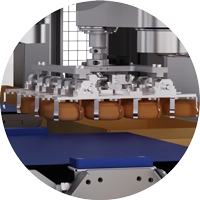

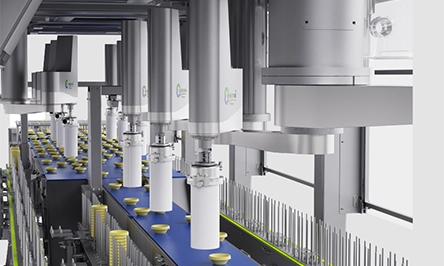

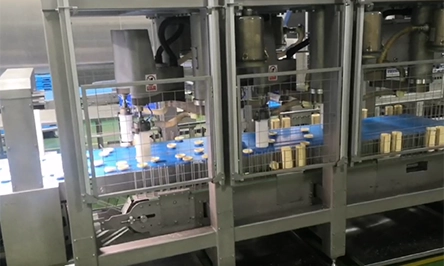

Scara robot for sorting and stacking incoming materials

Stable Working Quality

Most robot components use Food-Grade 304 stainless steel

Labour reduction according to robot ratio

Hengjiang change to Hexeon

System Solution

Advanced sensing and control

Carbon fiber rods: sturdy yet lightweight

High precision, high frequency

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• The robot system is capable of sorting incoming materials onto another conveyor belt for neat discharge into the packaging area..

• Precise control: advanced control system ensures stability of operation.

• Unique design allows to combine high speed and high precision to ensure stable, efficient product grabbing, stacking, and conveying even in freezing environments, greatly elevating line automation and production efficiency.

• Design flexibility: Simple adjustments enable sorting and packaging of a wide range of products (e.g., frozen donuts, frozen dumplings, frozen buns), medicines, electronics, and consumer, daily chemical items.

• Efficient, flexible, and precise characteristics significantly reduce production costs, elevate line automation and production efficiency, and improve product quality and market competitiveness.

EFFICIENTFLEXIBLEPRECISE

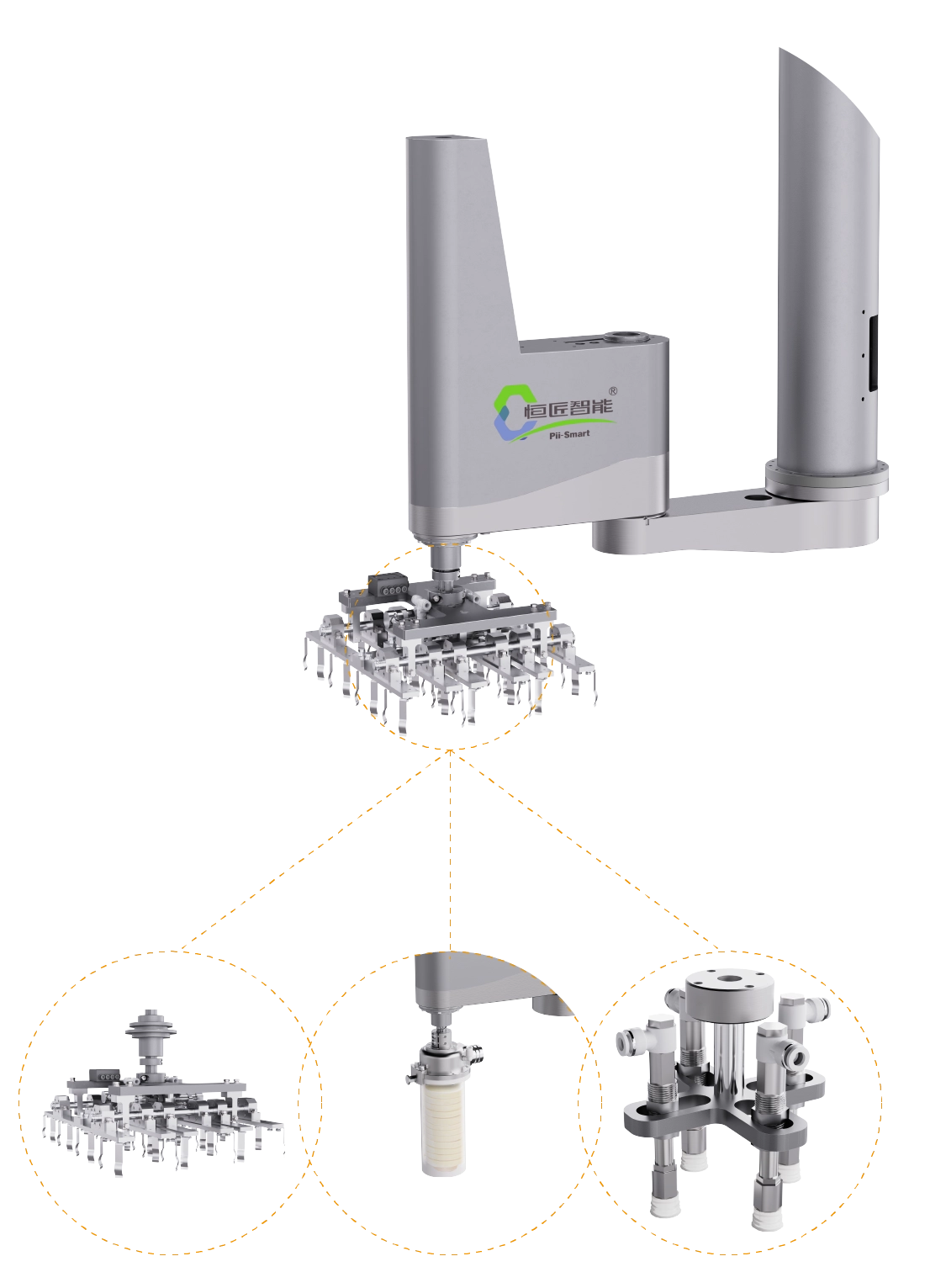

Scara Robot Grippers

By exchanging gripper designs to suit different materials, the system can finely grasp, sort, and carton a broad range of items.

To ensure food integrity and safety, grippers use food-grade materials; matching gripper types or suction cups to product shape and characteristics ensures precise placement into packaging boxes or other containers, with orderly transfer via conveyors to the next stage. |

|

|

|

|

| Technical Parameters |

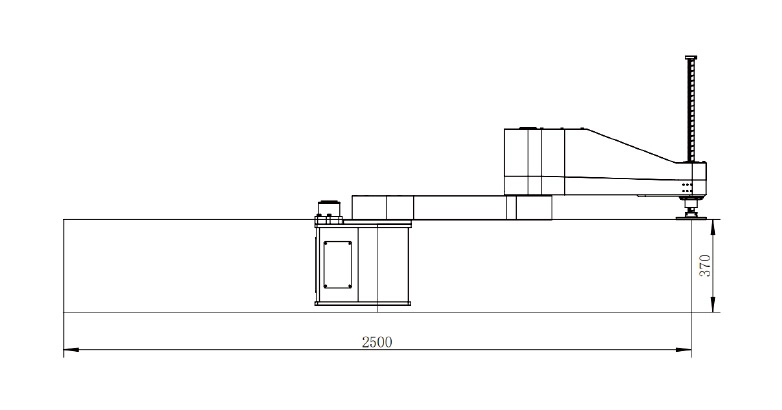

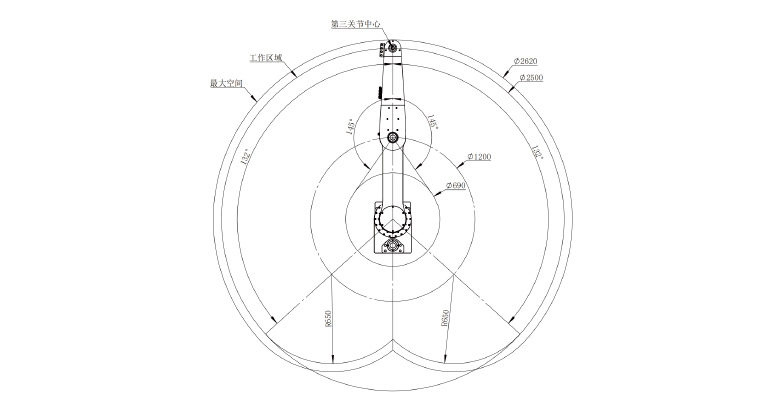

Equipment Name: Main Arm Length: Sub-arm Length: Z-axis Travel: Number of Axes: Repeat Positioning Accuracy: Travel radius: Maximum Operating Angle: Pick-up speed: Noise Level: Operating Range:

Maximum Speed:

Maximum Payload: Body Weight: Mounting Mode: |

HJ-SC1250-R 600mm 450mm 370mm 4 ±0.2mm 1250mm 270° 5-80Times/minute <68dB(A) 1-axis: ±170° 2-axis: -100°~+155° 3-axis: 370mm 4-axis: ±200° 1-axis: 300°/s 2-axis: 360°/s 3-axis: 500mm/s 4-axis: 900°/s 30kg Approximately 80 kg Grounded / Gantry |

| Product Advantage |

Intelligent vision control system: integrates advanced vision technology to identify and analyze the environment in real time, enabling precise positioning, adaptable to complex industrial scenes, and enhancing operational accuracy and efficiency. High-precision repeat positioning: positioning error less than 0.2 mm, ensuring consistency and stability, suitable for precision manufacturing and assembly. Horizontal multi-joint design: enhances flexibility, load capacity, and motion accuracy, balancing heavy handling with fine manipulation. Drive-control-electrical integrated design: integrates drive, controller, and power supply to simplify connections, improve system performance and reliability, and reduce energy consumption and maintenance costs. Advanced sensing control: configured with advanced sensors and self-developed control system, real-time perception of object shape, position, and force, enabling precise grasping and efficient handling, supporting dynamic strategy adjustments to enhance line adaptability and capacity. Stable working quality: equipped with high-precision motors and control systems, ensuring precise motion and stable trajectories, enabling long-term reliable operation, reducing downtime, and improving production efficiency. System solution: possesses proprietary core technologies, including motion control algorithms, sensor fusion, and path planning, supporting customized integration to help customers automate and modernize. Flexible task configuration: designed for rapid deployment and easy task switching, providing a concise programming interface to easily adjust working modes and programs, enhancing production flexibility and responsiveness. |

|

| Operating Environment |

Floor Load Capacity Vibration Interference |

Average Load ≧500kg/㎡ ≤0.5G Free from Strong Radio/Electromagnetic Interference |