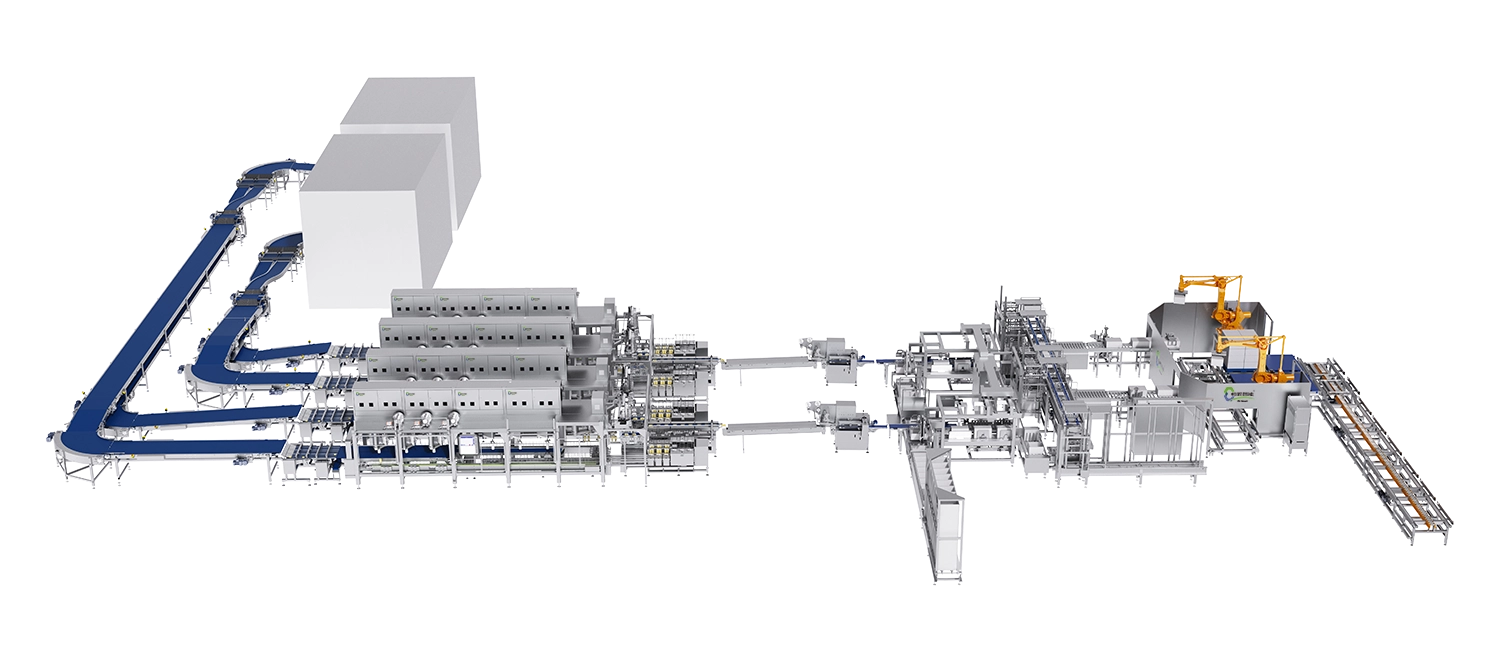

Frozen Tart Shell Sorting & Packaging Production Line (Case Study: SCARA Robot Sorting Workstation II) automates the handling of formed and frozen tart shells. The shells are transported via conveyor belt to SCARA robot workstations for sorting and stacking, then fed into bagging equipment, packed into foam boxes with ice, and neatly palletized.

This robotic packaging line spans from frozen tunnel docking to final palletizing, integrating sorting conveyors, stacking, combined packaging, sealing, and palletizing modules. It represents one of Hexseon’s intelligent factory solutions, designed to meet customized automation demands across diverse food industry scenarios.

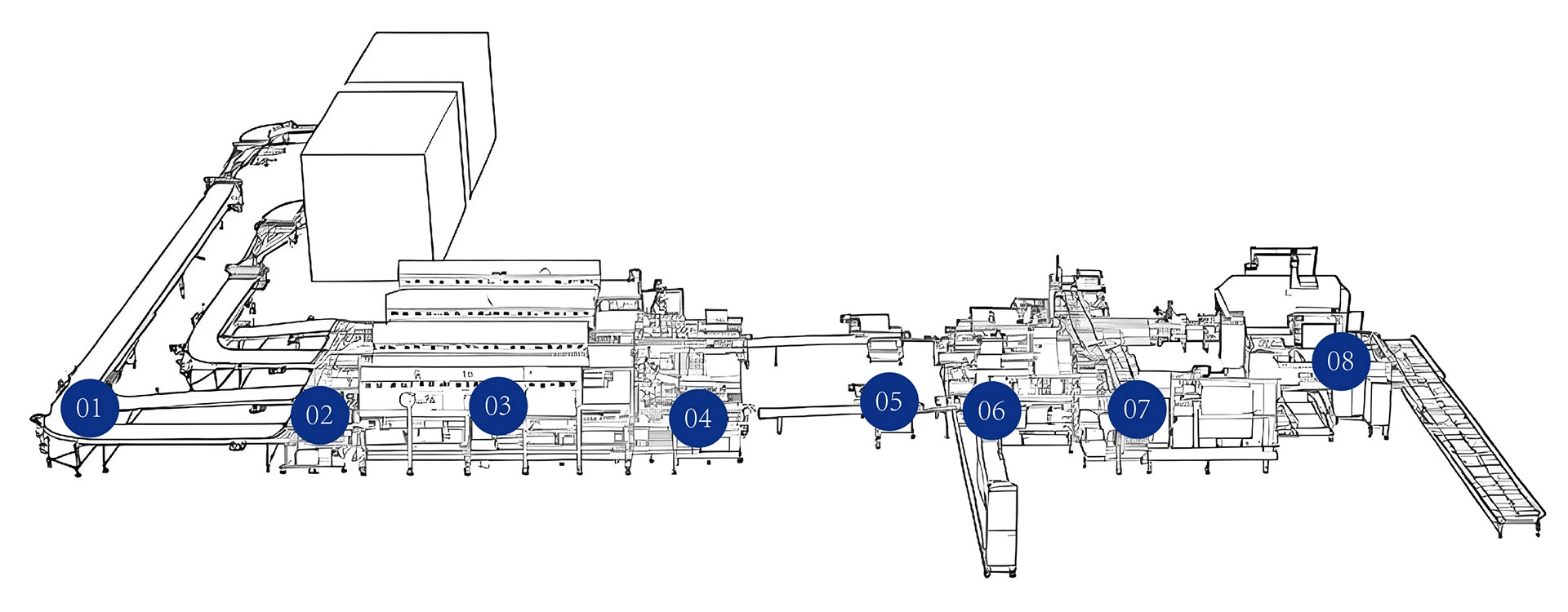

01 Conveyor Zone: Transports frozen egg tart shells from cold storage.

02 Alignment Zone: Arranges incoming shells into orderly rows.

03 SCARA Robot Workstation Zone: Four parallel stations sort shells simultaneously.

04 Sorting & Stacking Zone: Neatly stacks sorted shells onto packaging paper for transfer to the next stage.

05 Pillow Packaging & Sealing Zone: Seals products into bags.

06 Insulated Box Loading Zone: Places sealed bags into insulated containers.

07 Box Sealing Zone: Secures filled insulated boxes.

08 Palletizing Zone: Robotic arms neatly stack sealed boxes onto pallets.

Advanced Operating System for Efficient Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime to Cut Costs

User-Friendly Operation via Mobile, Tablet, PC, and Built-In Touchscreen

Smart Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Precise control: advanced control system ensures stability of operation.

| Technical Parameters |

Equipment Dimensions: Capacity Range: Total Power: Voltage: Air Pressure Requirement: Gas Consumption:

Conveyor Belt Line Speed: |

33500*16839*3500mm 40,000–80,000 units/hour 233KW AC380V+10-15% 0.6MPa(6Kg/cm²) 2.5m³/min 5-12m/min |

| Product Advantages |

Maximum user friendliness. Simplified operation for ease of use. Remote accessibility for maintenance and troubleshooting. Adaptable for quick changeovers between multiple product types. |

|

| Operating Environment |

Floor Load Capacity Ambient Temperature Ambient Humidity Vibration Interference |

Average Load ≥500kg/m² 5-40℃ No Frost/Condensation Within Max 75% Humidity ≤0.5G Free from Strong Radio/Electromagnetic Interference |