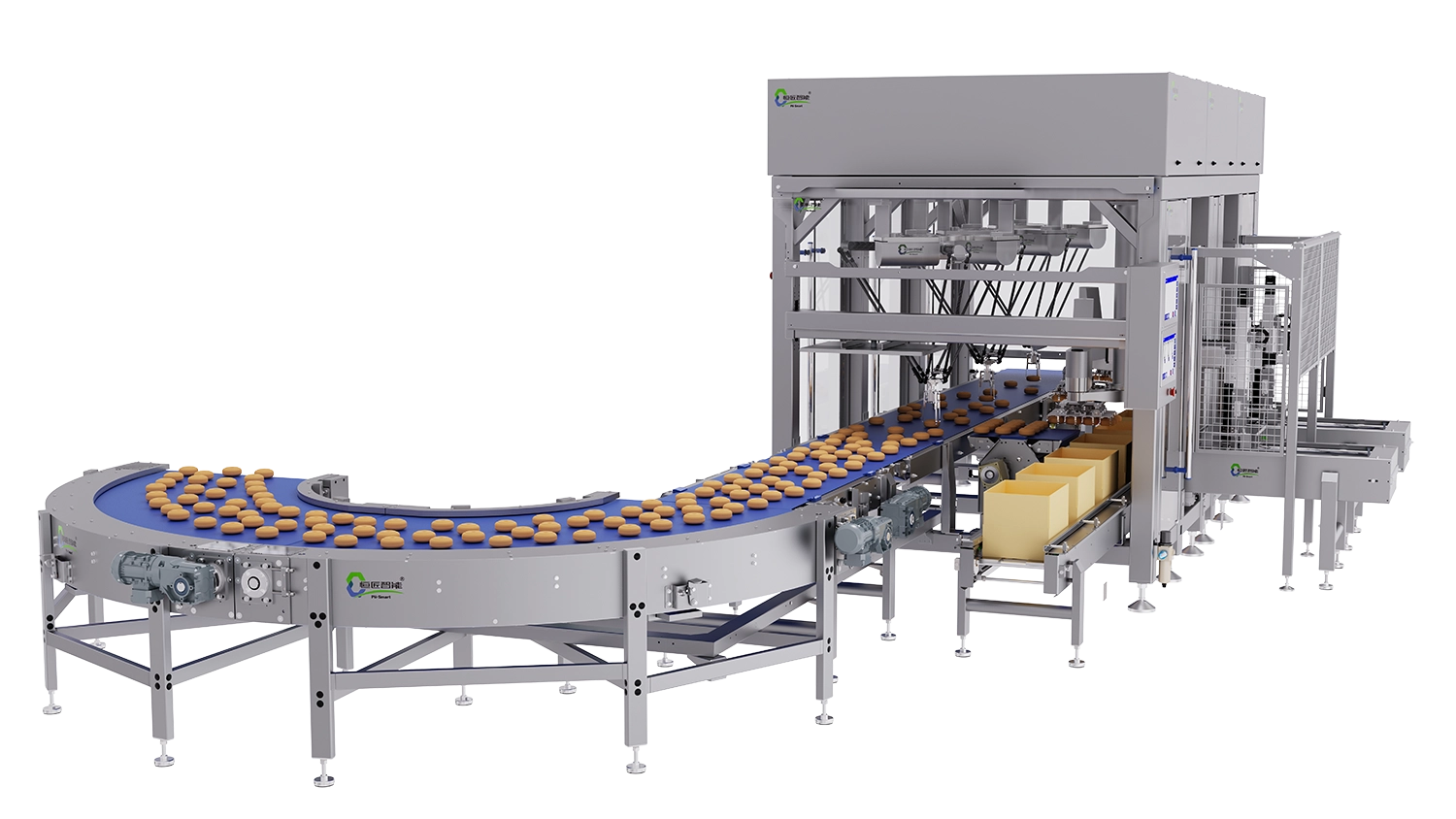

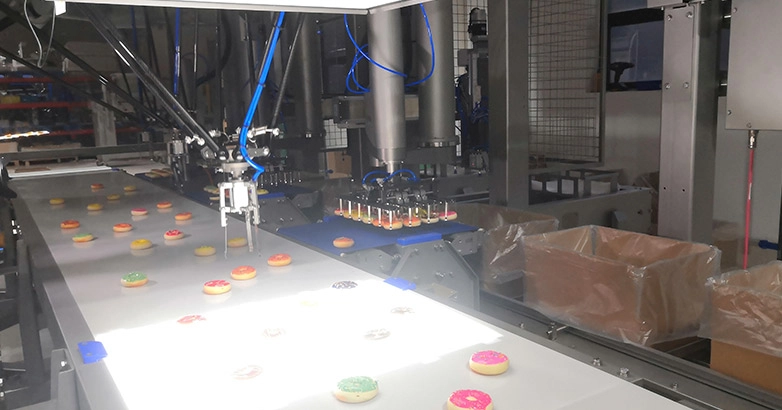

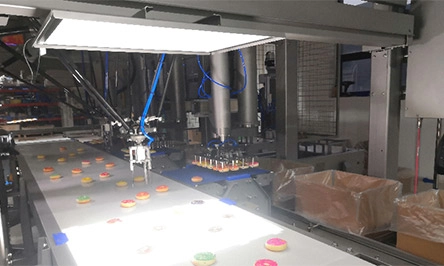

This workstation utilizes Delta robots to grip incoming donuts and arrange them in a single row on a side conveyor belt. SCARA robots then transfer the neatly aligned donuts into cardboard boxes lined with plastic bags, placing a layer of greaseproof paper between each row via SCARA-assisted placement. The packaged donuts are conveyed to the next packaging stage. The system integrates both Delta and SCARA robots for seamless operation.

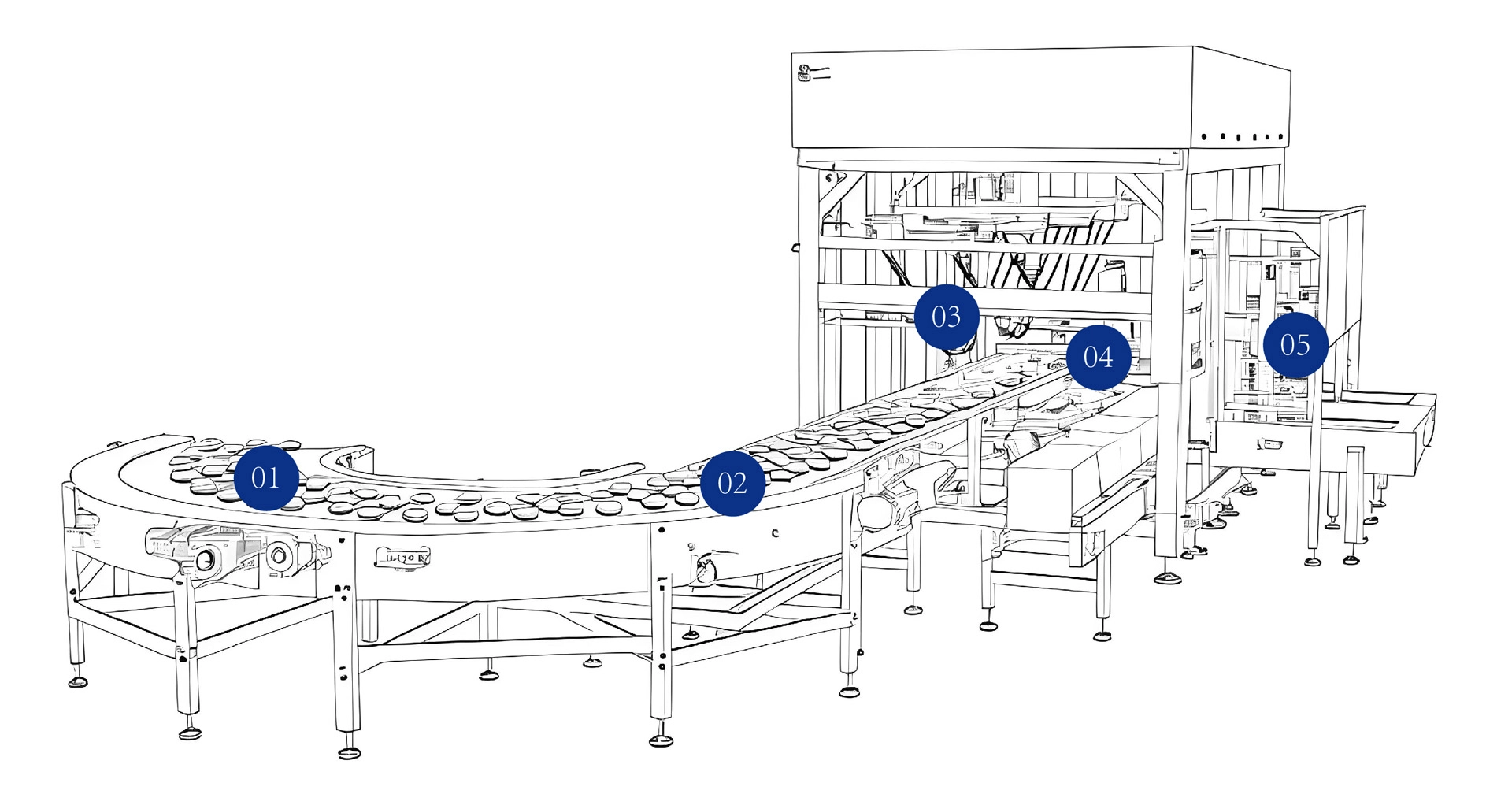

01 Product Conveyance

02 Product Positioning

03 Sorting & Storage

04 Placement & Cartoning

05 Defect Removal

Advanced Operating System for Efficient Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime to Cut Costs

User-Friendly Operation via Mobile, Tablet, PC, and Built-In Touchscreen

Smart Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Precise control: advanced control system ensures stability of operation.

| Technical Parameters |

Equipment Dimensions: Voltage: Power Supply Capacity: Air Pressure Requirement: Flow Rate: |

9132*5576*2671mm AC380V / AC220V / DC24V 20KW >0.6MPa(6Kg/cm²) >2m³/min |

| Operating Environment |

Floor Load Capacity Ambient Temperature Ambient Humidity Vibration Interference |

Average Load ≥500kg/m² 5-40℃ Max75% or less No frost, no dew ≤0.5G Free from Strong Radio/Electromagnetic Interference |