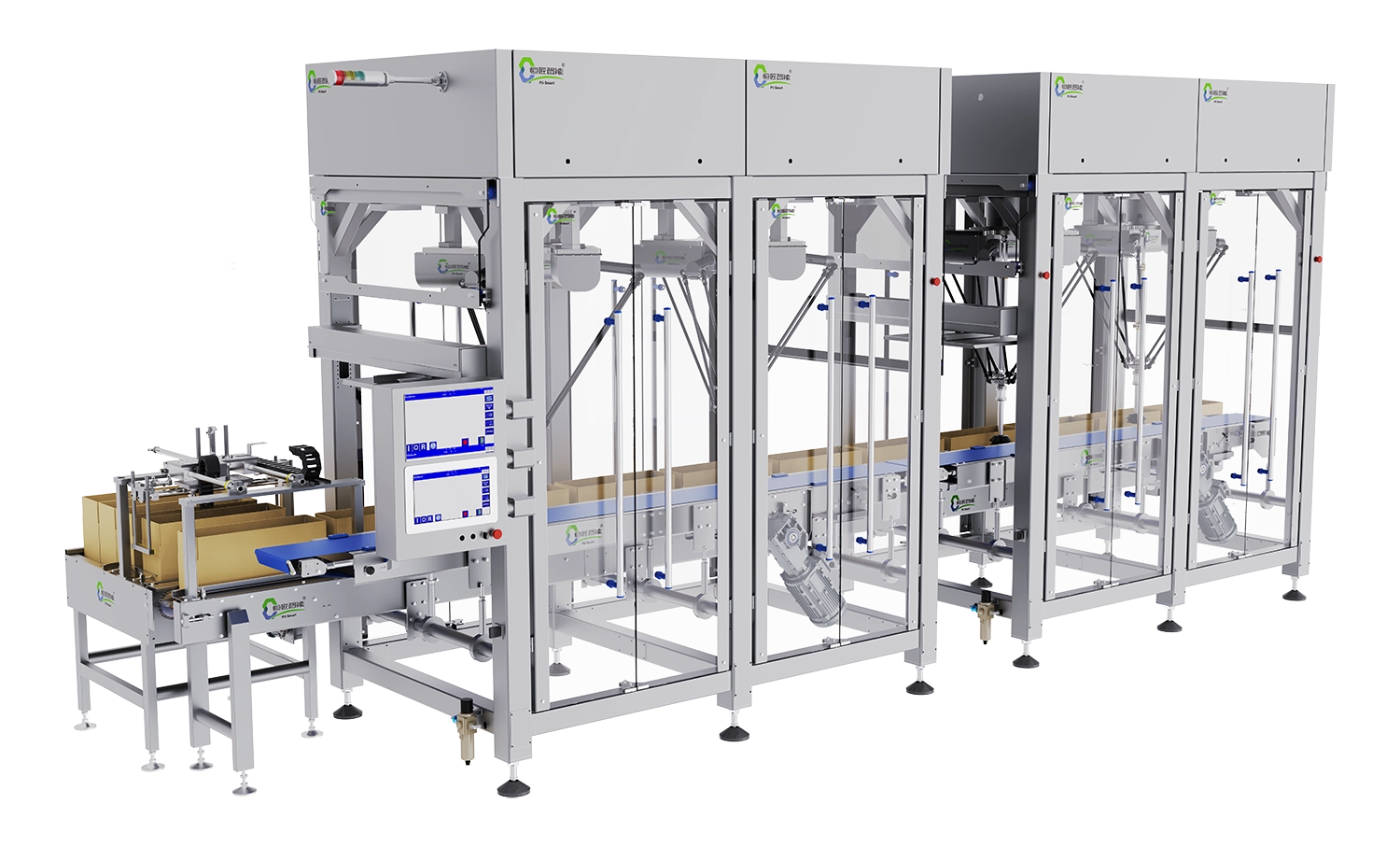

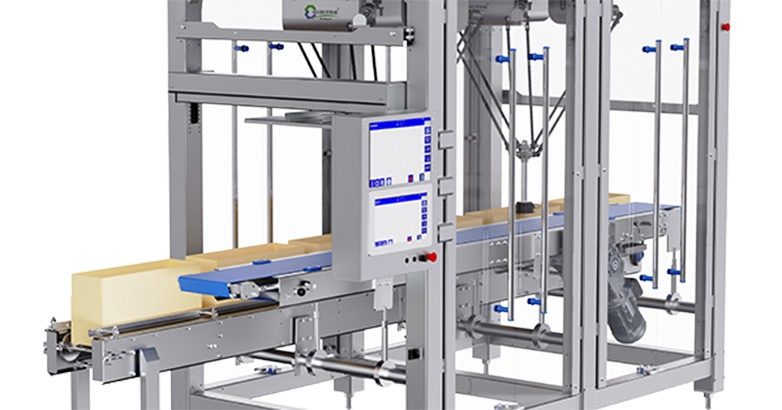

Pizza Sorting & Packaging Line B is a highly efficient automated packaging system designed specifically for frozen pizza packaging, while also adaptable for sorting and cartoning other foods, pharmaceuticals, electronics, daily chemical products, and more. By integrating conveyor positioning, visual recognition, parallel robot gripping, and automated cartoning, it achieves precise, high-speed packaging, significantly enhancing production line automation, efficiency, and cost-effectiveness while strengthening product competitiveness.

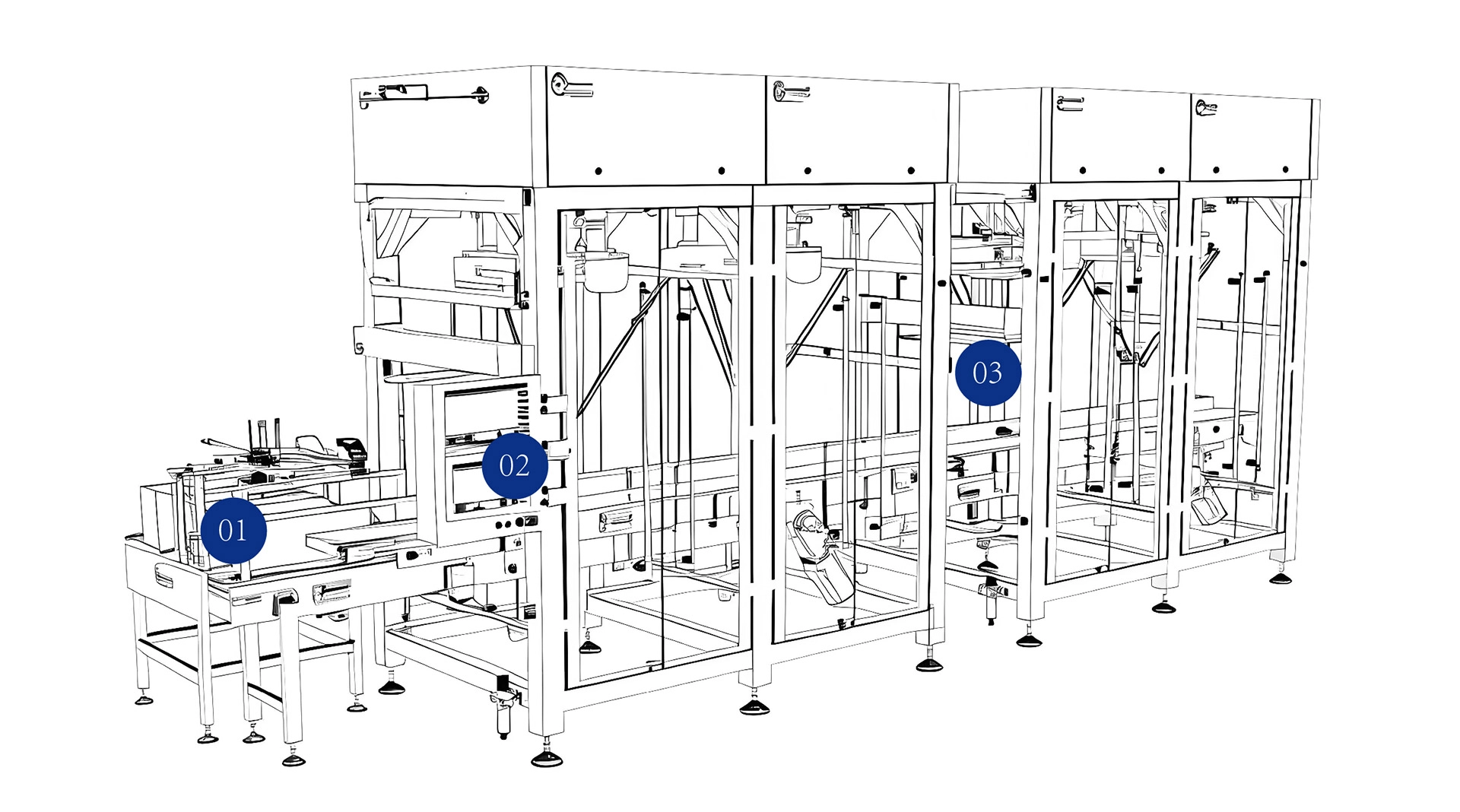

01 Feeding & Alignment: Incoming materials enter the workstation steadily and continuously via conveyor chains.

02 Self-developed patent operating system, tightly matched to production systems to ensure throughput, with mobile, tablet, computer, and built-in touch-screen operation modes

03 The visual recognition system identifies incoming products, enabling robots to sort and align irregular items onto conveyors for downstream processing.

Advanced Operating System for Efficient Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime to Cut Costs

User-Friendly Operation via Mobile, Tablet, PC, and Built-In Touchscreen

Smart Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production

• Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Precise control: advanced control system ensures stability of operation.

| Technical Parameters |

Equipment Dimensions: Voltage: Power Supply Capacity: Air Pressure Requirement: Flow Rate: Conveyor Belt Line Speed: |

AC380V+10-15% >215KVA >0.6MPa(6Kg/cm²) >2m³/min 430mm/s |

| Product Advantages |

Food Safety Compliance: Designed to meet food-grade safety standards, using dust-free environments and food-safe lubricants to ensure hygiene. High Automation: Precise material handling minimizes waste and labor costs by eliminating dropouts. Modular Design: Customizable modules cater to diverse robotic needs, adapting to any production requirement. Cold Environment Adaptability: Maintains stable, high-efficiency performance in freezing conditions for tasks like grasping, stacking, and conveying. Versatility: Streamlines production with integrated automation for stacking, conveying, and transferring products flexibly. Safety Protections: Built-in safeguards, including guardrails and safety doors, ensure operator security. High Speed & Precision: Delivers rapid, accurate grasping to boost efficiency and product quality. Pneumatic Grippers: The end-effector uses pneumatic grippers for reliable grasping/stacking, with interchangeable tools for diverse food handling. |

|

| Operating Environment |

Floor Load Capacity Ambient Temperature Ambient Humidity Vibration Interference |

Average Load ≥500kg/m² 5-40℃ Max75% or less No frost, no dew ≤0.5G Free from Strong Radio/Electromagnetic Interference |