Delta Robot Donut Sorting Workstation is a high-end solution independently developed by Hexeon Intelligent for food industry automation. Featuring a modular design, it can be flexibly configured to meet diverse production needs of varying scales and product types. Leveraging the unique high-speed, high-precision capabilities of Delta robots, this workstation ensures stable and efficient execution of product grasping, stacking, and conveying tasks—even in frozen environments—significantly enhancing production line automation and efficiency. The format of the line can be adjusted to ideally fit for sorting and packaging various frozen food products (e.g., donuts, dumplings, steamed buns), pharmaceuticals, electronics, and daily chemicals, its adaptability allows seamless integration into inner packaging lines for various items. By optimizing automation, reducing costs, and improving product quality, it strengthens market competitiveness.

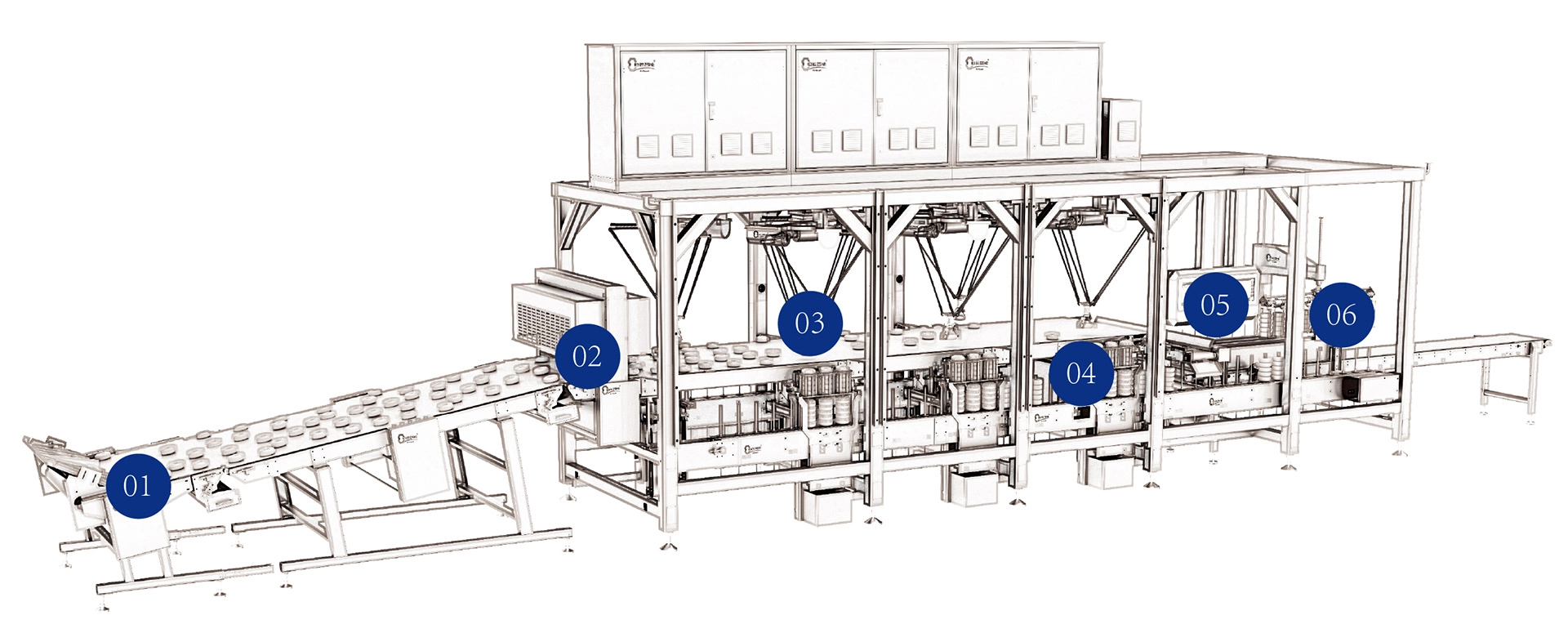

01 Buffer Docking: Feeding & Alignment, Deceleration & Arrangement

02 Vision Positioning System: Acceleration & Visual Inspection

03 Actuator Assembly & Stacking Conveyor System: Sorting & Placement

04 Stacking Buffer System: Stacking & Aggregation

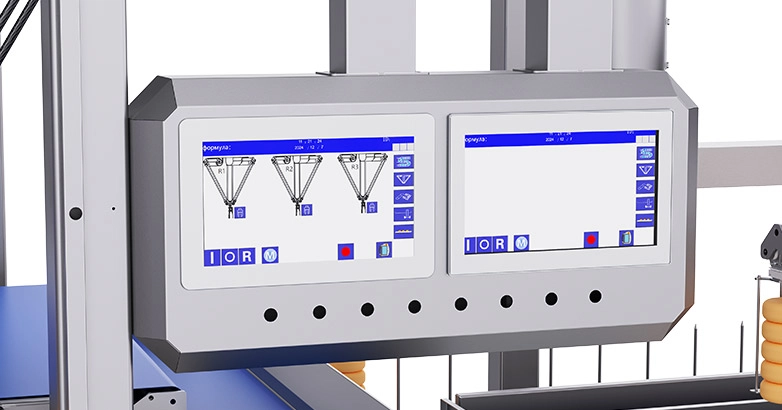

05 Human-Machine Interface

06 Aggregation System: Magazine-Style Feeding

Advanced Operating System for Efficient Production

Quick & Easy Cleaning Mode

Advanced Design Minimizes Downtime to Cut Costs

User-Friendly Operation via Mobile, Tablet, PC, and Built-In Touchscreen

Smart Efficiency for Reduced Energy Consumption

• Patented operating system, highly compatible with production systems to ensure output capacity. Supports smartphones, tablets, computers, and touchscreen operation modes for highest convenience and control of the production.

•Intuitive operation, beginner-friendly touchscreen design suitable even for semi-skilled personnel.

• Precise control: advanced control system ensures stability of operation.

| Technical Parameters |

Equipment Dimensions Voltage Power Supply Capacity Air Pressure Requirement Flow Rate Maximum Capacity Gas Consumption

Conveyor Belt Line Speed |

14250*2150*3750mm AC380V+10-15% >215KVA >0.6MPa(6Kg/cm²) >2m³/min 320 per/min 2000m³/min 430mm/s |

| Product Advantages |

Food Safety Compliance: Designed to meet food-grade safety standards, using dust-free environments and food-safe lubricants to ensure hygiene. High Automation: Precise material handling minimizes waste and labor costs by eliminating dropouts. Modular Design: Customizable modules cater to diverse robotic needs, adapting to any production requirement. Cold Environment Adaptability: Maintains stable, high-efficiency performance in freezing conditions for tasks like grasping, stacking, and conveying. Versatility: Streamlines production with integrated automation for stacking, conveying, and transferring products flexibly. Donut-Specific Application: Positioned post-freezing tunnel for inner packaging, replacing manual sorting to boost efficiency. High Throughput: Up to 450 donuts/minute. Safety Protections: Built-in safeguards, including guardrails and safety doors, ensure operator security. High Speed & Precision: Delivers rapid, accurate grasping to boost efficiency and product quality.

Pneumatic Grippers: The end-effector uses pneumatic grippers for reliable grasping/stacking, with interchangeable tools for diverse food handling. |

|

| Operating Environment |

Floor Load Capacity Ambient Temperature Ambient Humidity Vibration Interference |

Average Load ≥500kg/m² 5-40℃ Max75% or less No frost, no dew ≤0.5G Free from Strong Radio/Electromagnetic Interference |