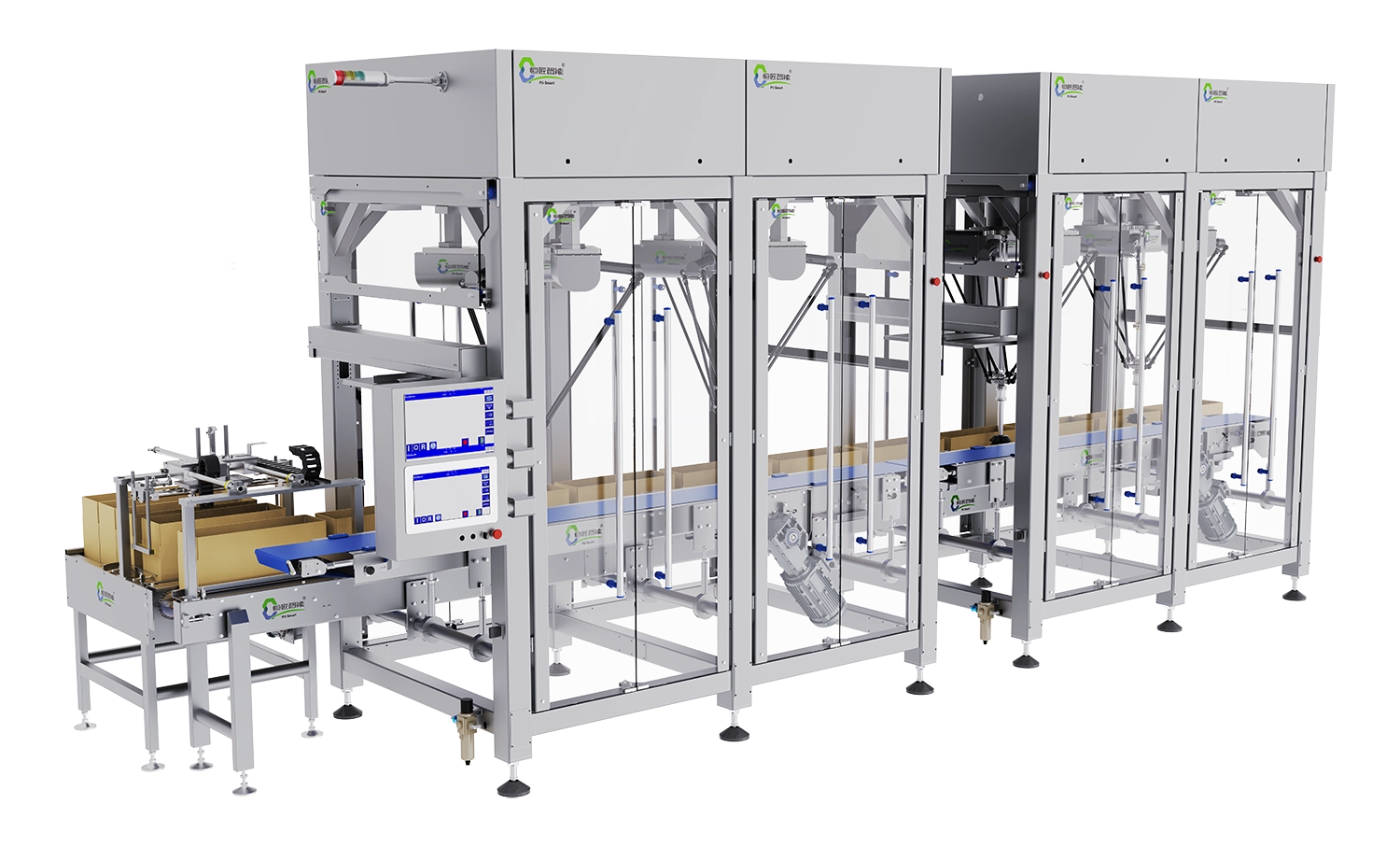

The Automated Pizza Sorting Packaging Line developed by Hengjiang Intelligent Technology Co., Ltd. is a high-performance, fully automated packaging solution engineered specifically for the high-throughput demands of frozen pizza production, while maintaining exceptional flexibility for cross-industry applications. By deeply integrating intelligent conveying systems, industrial vision positioning, parallel Delta robot picking, and synchronized automated cartoning, this system enables precise, stable, and continuous packaging operations even under low-temperature and high-speed production environments. Designed with scalability and modularity in mind, the line not only significantly improves packaging efficiency and consistency, but also reduces manual labor dependence, minimizes product handling damage, and enhances overall production line automation levels, helping manufacturers strengthen cost control, product quality, and long-term market competitiveness.

The Automated Pizza Sorting Packaging Line performs a complete sequence of intelligent product handling functions, starting from incoming frozen product conveyance through final carton loading and transfer to downstream packaging stages. Frozen pizzas arriving from upstream production lines are smoothly transported via precision-controlled conveyor belts, where their position, orientation, and spacing are continuously stabilized to ensure optimal robot gripping conditions. An overhead industrial vision system captures real-time images of each product, accurately calculating coordinates and feeding positioning data to the Delta robots. Based on this visual recognition, multiple Delta robots operate in parallel to rapidly pick pizzas and place them into cartons with consistent alignment and stacking accuracy. Once the preset number of rows is completed, the system automatically advances the carton using a synchronized chain conveyor and push-bar mechanism, ensuring seamless handover to sealing, labeling, or secondary packaging equipment. Beyond frozen pizza, the system is equally suitable for sorting and cartoning frozen doughnuts, dumplings, steamed buns, pharmaceutical blister packs, electronic components, and daily chemical products that require high-speed, high-precision packaging.

This automated packaging line stands out due to its advanced combination of parallel Delta robot architecture, industrial machine vision, and high-precision synchronized conveyors, all engineered to operate reliably in frozen or demanding production environments. The use of multiple Delta robots working simultaneously significantly increases throughput while maintaining consistent placement accuracy, making the system ideal for mass production lines with strict efficiency requirements. The vision system enables non-contact product detection, allowing for random product orientation on the infeed conveyor without compromising picking accuracy. Modular mechanical design allows the line to be easily expanded, reconfigured, or integrated into existing factory layouts. Food-grade materials, hygienic structural design, and easy-clean surfaces ensure compliance with food safety standards, while robust control logic and servo-driven motion systems guarantee stable long-term operation. Additionally, the system supports quick changeover for different product sizes and carton formats, reducing downtime and improving production flexibility.

The Automated Pizza Sorting Packaging Line is built using industrial-grade components and configurable parameters to meet diverse production needs. Typical configurations include dual or multi-Delta robot setups, high-speed belt or modular chain conveyors, and high-resolution industrial cameras with real-time image processing capabilities. The system supports a wide range of pizza diameters, thicknesses, and packaging quantities per carton, with adjustable gripping tools to accommodate different product textures and packaging requirements. Operating speeds can be customized according to production targets, with stable performance maintained even at high cycle rates. The control system integrates PLC and robot controllers with a user-friendly HMI interface, enabling real-time monitoring, parameter adjustment, fault diagnostics, and production data tracking. Power supply, compressed air requirements, and environmental temperature ranges are designed to meet the demands of frozen food processing plants and industrial packaging environments.

While originally developed for frozen pizza packaging, this automated sorting and cartoning solution is widely applicable across multiple industries that demand high-speed, high-precision product handling. In the food industry, it is ideal for frozen bakery products, prepared meals, dough-based items, and snack foods. In the pharmaceutical industry, the system can be adapted for cartoning blister packs, bottles, or medical consumables requiring clean and accurate placement. In electronics manufacturing, it supports the orderly packing of components, accessories, or finished devices. The daily chemical industry also benefits from its ability to handle boxed or wrapped consumer goods with consistent positioning and high throughput. This broad applicability makes the line a versatile automation investment for manufacturers seeking long-term flexibility.

The Automated Pizza Sorting Packaging Line is designed for medium to large-scale food manufacturers, frozen food processing plants, central kitchens, and OEM packaging integrators seeking to upgrade from manual or semi-automatic operations to fully automated, intelligent production lines. It is particularly suitable for enterprises facing rising labor costs, increasing production volumes, and higher quality consistency requirements. Additionally, pharmaceutical, electronics, and daily chemical manufacturers looking for reliable, robot-based cartoning solutions will find this system an ideal choice. By adopting this advanced automation solution from Hengjiang Intelligent Technology Co., Ltd., customers can achieve sustainable efficiency gains, improved product presentation, reduced operational risks, and stronger competitiveness in both domestic and international markets.